English

English  Esperanto

Esperanto Afrikaans

Afrikaans Català

Català שפה עברית

שפה עברית Cymraeg

Cymraeg Galego

Galego Latviešu

Latviešu icelandic

icelandic ייִדיש

ייִדיש беларускі

беларускі Hrvatski

Hrvatski Kreyòl ayisyen

Kreyòl ayisyen Shqiptar

Shqiptar Malti

Malti lugha ya Kiswahili

lugha ya Kiswahili አማርኛ

አማርኛ Bosanski

Bosanski Frysk

Frysk ភាសាខ្មែរ

ភាសាខ្មែរ ქართული

ქართული ગુજરાતી

ગુજરાતી Hausa

Hausa Кыргыз тили

Кыргыз тили ಕನ್ನಡ

ಕನ್ನಡ Corsa

Corsa Kurdî

Kurdî മലയാളം

മലയാളം Maori

Maori Монгол хэл

Монгол хэл Hmong

Hmong IsiXhosa

IsiXhosa Zulu

Zulu Punjabi

Punjabi پښتو

پښتو Chichewa

Chichewa Samoa

Samoa Sesotho

Sesotho සිංහල

සිංහල Gàidhlig

Gàidhlig Cebuano

Cebuano Somali

Somali Тоҷикӣ

Тоҷикӣ O'zbek

O'zbek Hawaiian

Hawaiian سنڌي

سنڌي Shinra

Shinra Հայերեն

Հայերեն Igbo

Igbo Sundanese

Sundanese Lëtzebuergesch

Lëtzebuergesch Malagasy

Malagasy Yoruba

Yoruba অসমীয়া

অসমীয়া ଓଡିଆ

ଓଡିଆ Español

Español Português

Português русский

русский Français

Français 日本語

日本語 Deutsch

Deutsch tiếng Việt

tiếng Việt Italiano

Italiano Nederlands

Nederlands ภาษาไทย

ภาษาไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা ভাষার

বাংলা ভাষার Dansk

Dansk Suomi

Suomi हिन्दी

हिन्दी Pilipino

Pilipino Türkçe

Türkçe Gaeilge

Gaeilge العربية

العربية Indonesia

Indonesia Norsk

Norsk تمل

تمل český

český ελληνικά

ελληνικά український

український Javanese

Javanese فارسی

فارسی தமிழ்

தமிழ் తెలుగు

తెలుగు नेपाली

नेपाली Burmese

Burmese български

български ລາວ

ລາວ Latine

Latine Қазақша

Қазақша Euskal

Euskal Azərbaycan

Azərbaycan Slovenský jazyk

Slovenský jazyk Македонски

Македонски Lietuvos

Lietuvos Eesti Keel

Eesti Keel Română

Română Slovenski

Slovenski मराठी

मराठी Srpski језик

Srpski језик

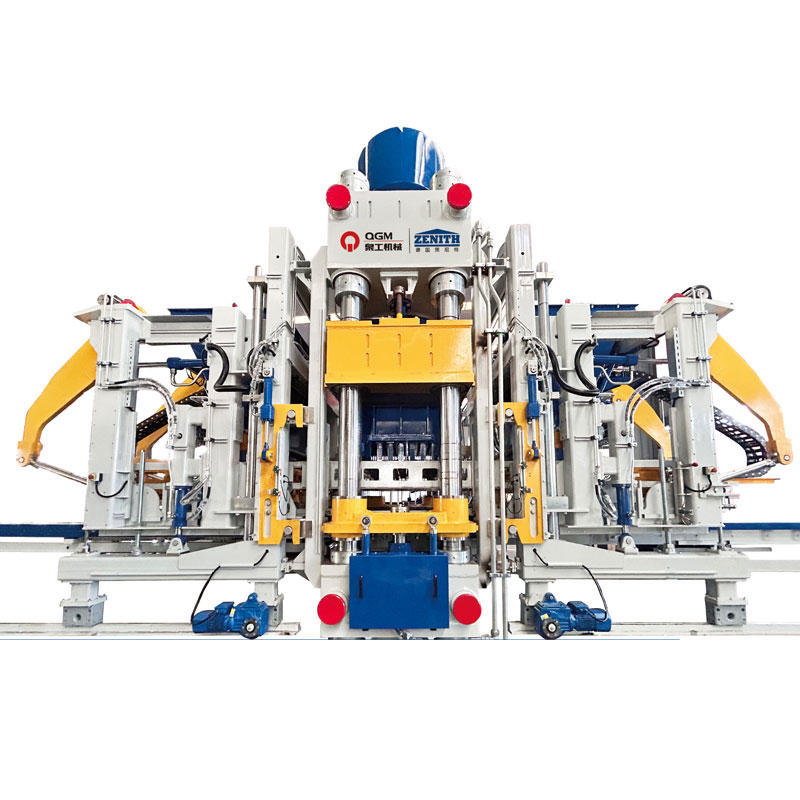

Wall Retaining Block Mould

Send Inquiry

You can rest assured to buy Wall Retaining Block Mould from our factory. QGM retaining wall block mould adopts low carbon allay high strength carburizing steel, hardness reaches 60-63HRC, combined withadvanced welding and processing technology dearance 0.8-1mm, which make the mould strong and durable. Meanwhile, mould platesand spare parts can be easily replaced.

Compared with other Wall Retaining Block Mould, the design of retaining wall blocks has more complicated requirements. With decades of experience, QGM can provide integrated solutions to help customers achieve the unity of appearance and function.

Whether it is the anchorage of slopes which serve to prevent the slipping of the soil, or the design and beautification of public areas in cities and towns or even only the herb spiral in your own garden-the applications are multifaceted, better and very simple to handle. Especially at the beginning of the planning phase, our project team will assist our customers in giving the right look to a functioning system. ZENITH Formen has both the necessary experience and the know-how:

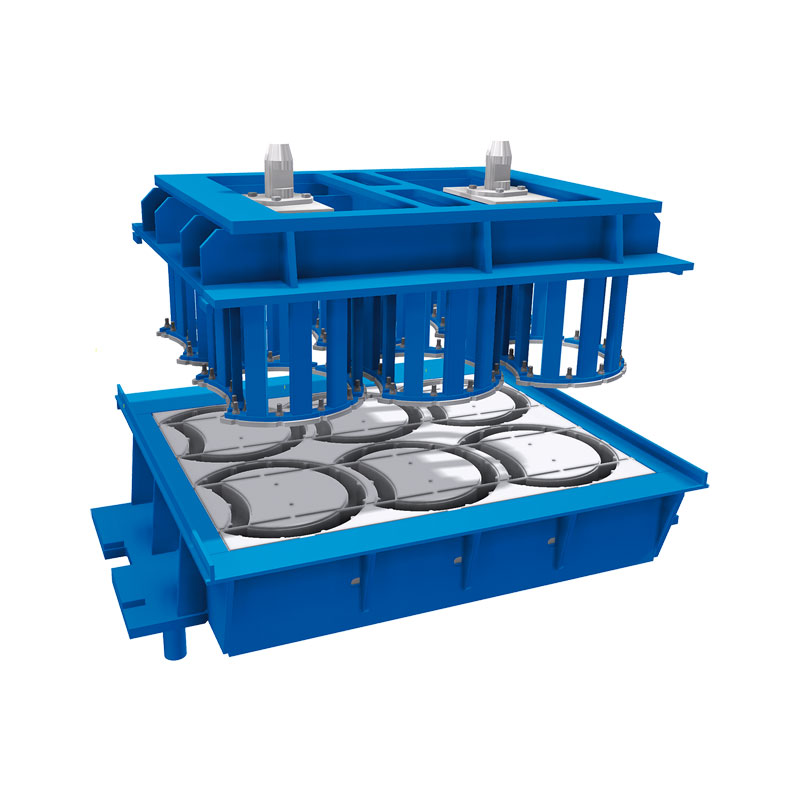

Mold design

QGM utilizes a combination of advanced welding and processing technologies.

Materials: high quality wear-resistant steel

The clearance between tamper shoes is 0.5-0.8mm.

The tamper shoes can be easily replaced

The design is sturdy, durable and proven.

Molds can be changed for customers

The quick-wear parts can be easily replaced

The mold frame is equipped with a hydraulic device and the frame board can be folded as needed.

Inner parts can be conducted nitrogen treatment 62-68HRC

We always maintain open communication with customers in order to ensure the exact mold design. When the concrete product thickness is less than 50mm, we will consult a mechanical manufacturer for advice.

Our production line covers a broad range of concrete mould applications, e.g. moulds for floor-layers, multi-layer and stationary machines. We have also acquired know-how and experience over decades in very specific fields, such as tilt stone-, split block and casting mould production technologies and are therefore clearly in a position to be able to convince you with top-quality and top-solutions.