English

English  Esperanto

Esperanto Afrikaans

Afrikaans Català

Català שפה עברית

שפה עברית Cymraeg

Cymraeg Galego

Galego Latviešu

Latviešu icelandic

icelandic ייִדיש

ייִדיש беларускі

беларускі Hrvatski

Hrvatski Kreyòl ayisyen

Kreyòl ayisyen Shqiptar

Shqiptar Malti

Malti lugha ya Kiswahili

lugha ya Kiswahili አማርኛ

አማርኛ Bosanski

Bosanski Frysk

Frysk ភាសាខ្មែរ

ភាសាខ្មែរ ქართული

ქართული ગુજરાતી

ગુજરાતી Hausa

Hausa Кыргыз тили

Кыргыз тили ಕನ್ನಡ

ಕನ್ನಡ Corsa

Corsa Kurdî

Kurdî മലയാളം

മലയാളം Maori

Maori Монгол хэл

Монгол хэл Hmong

Hmong IsiXhosa

IsiXhosa Zulu

Zulu Punjabi

Punjabi پښتو

پښتو Chichewa

Chichewa Samoa

Samoa Sesotho

Sesotho සිංහල

සිංහල Gàidhlig

Gàidhlig Cebuano

Cebuano Somali

Somali Тоҷикӣ

Тоҷикӣ O'zbek

O'zbek Hawaiian

Hawaiian سنڌي

سنڌي Shinra

Shinra Հայերեն

Հայերեն Igbo

Igbo Sundanese

Sundanese Lëtzebuergesch

Lëtzebuergesch Malagasy

Malagasy Yoruba

Yoruba অসমীয়া

অসমীয়া ଓଡିଆ

ଓଡିଆ Español

Español Português

Português русский

русский Français

Français 日本語

日本語 Deutsch

Deutsch tiếng Việt

tiếng Việt Italiano

Italiano Nederlands

Nederlands ภาษาไทย

ภาษาไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা ভাষার

বাংলা ভাষার Dansk

Dansk Suomi

Suomi हिन्दी

हिन्दी Pilipino

Pilipino Türkçe

Türkçe Gaeilge

Gaeilge العربية

العربية Indonesia

Indonesia Norsk

Norsk تمل

تمل český

český ελληνικά

ελληνικά український

український Javanese

Javanese فارسی

فارسی தமிழ்

தமிழ் తెలుగు

తెలుగు नेपाली

नेपाली Burmese

Burmese български

български ລາວ

ລາວ Latine

Latine Қазақша

Қазақша Euskal

Euskal Azərbaycan

Azərbaycan Slovenský jazyk

Slovenský jazyk Македонски

Македонски Lietuvos

Lietuvos Eesti Keel

Eesti Keel Română

Română Slovenski

Slovenski मराठी

मराठी Srpski језик

Srpski језик

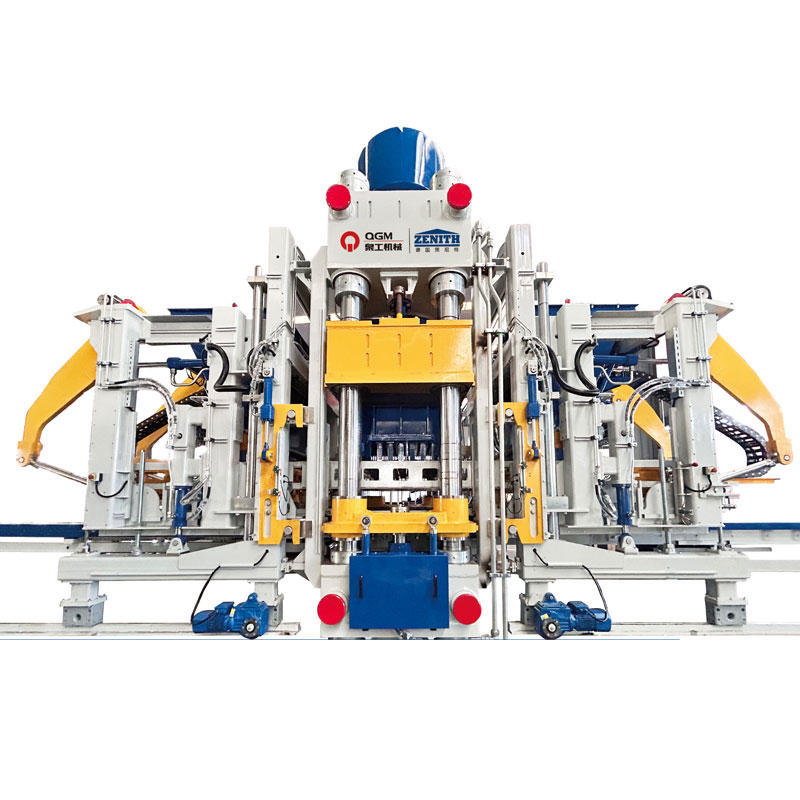

Paver Mould

Send Inquiry

As the professional manufacturer, we would like to provide you Paver Mould. QGM paver mould adopts low carbon alloy high strength carburizing steel and integrates precise wiring cutting technologyhigh-precision CNC processing technolbgy and 3D scanning technology to provide custamers with mould customization. These technologies can design a vaniety of contours and geometric shapes.Its clearance of 0.3-0.4mm, with precise vertical corners ands:mooth sidewalls. Pavers produced by QGM are easy-demoulding, high precision, no burrs around. Moulds can realize digital freesurface design and pressure plates interchange design.

In order to ensure the durability of the mould, QGM paver mould adopts carbunizing treatment., mould framies and pressure plates are hardened 60-63HRC, and the mirnimuim hardening depth is 1.2m.According to customers'requests, the mould can be designed and manufactured by welding or modular thread locking.

We offer high quality Paver Moulds for all types of machines and tool fittings in the following design:

A)MOULD DESIGN FLAME CUT

Narrow web thicknesses feasible

Optimal exploitation of the mould

Machine dependent stamp shoe clearance of 0,2-0,5 mm

Counter-conical side walls feasible

No holding grooves necessary

Typical design for multilayer production machinery

Optional withdraw sheet design

By digitalization free surface design realizable

Heatable stamp shoe design viable

B)MOULD DESIGN MILLED

Applicable to all contours and geometries

Tolerances in the mould box below +/-0.3 mm

Machine dependent stamp shoe clearance of 0,2-0,5 mm

Precise vertical, angled and smooth side walls

Easy demoulding

High accuracy of fit

Space holders in all possible designs feasible

Optional withdraw sheet design

By digitalization free surface design realizable

Heatable stamp shoe design viable

Wear protection for all pavement moulds as follows:

A)CARBURIZING(62-68 HRC)

Mould box and stamp shoes hardened (62-68 HRC)

Hardness penetration min. 1,2 mm

B)NITRATING (62-68 HRC)

Mould box and stamp shoes nitrated (62-68 HRC)

Hardness penetration min. 0,4 mm

Hardly any internal stress compared to moulds treated by carburizing

Recommended for small web thicknesses

Higher contour accuracy over moulds treated by carburizing

Following the requirements from customers, our molds can be designed and manufactured in weld or modular screw thread locking methods.