English

English  Esperanto

Esperanto Afrikaans

Afrikaans Català

Català שפה עברית

שפה עברית Cymraeg

Cymraeg Galego

Galego Latviešu

Latviešu icelandic

icelandic ייִדיש

ייִדיש беларускі

беларускі Hrvatski

Hrvatski Kreyòl ayisyen

Kreyòl ayisyen Shqiptar

Shqiptar Malti

Malti lugha ya Kiswahili

lugha ya Kiswahili አማርኛ

አማርኛ Bosanski

Bosanski Frysk

Frysk ភាសាខ្មែរ

ភាសាខ្មែរ ქართული

ქართული ગુજરાતી

ગુજરાતી Hausa

Hausa Кыргыз тили

Кыргыз тили ಕನ್ನಡ

ಕನ್ನಡ Corsa

Corsa Kurdî

Kurdî മലയാളം

മലയാളം Maori

Maori Монгол хэл

Монгол хэл Hmong

Hmong IsiXhosa

IsiXhosa Zulu

Zulu Punjabi

Punjabi پښتو

پښتو Chichewa

Chichewa Samoa

Samoa Sesotho

Sesotho සිංහල

සිංහල Gàidhlig

Gàidhlig Cebuano

Cebuano Somali

Somali Тоҷикӣ

Тоҷикӣ O'zbek

O'zbek Hawaiian

Hawaiian سنڌي

سنڌي Shinra

Shinra Հայերեն

Հայերեն Igbo

Igbo Sundanese

Sundanese Lëtzebuergesch

Lëtzebuergesch Malagasy

Malagasy Yoruba

Yoruba অসমীয়া

অসমীয়া ଓଡିଆ

ଓଡିଆ Español

Español Português

Português русский

русский Français

Français 日本語

日本語 Deutsch

Deutsch tiếng Việt

tiếng Việt Italiano

Italiano Nederlands

Nederlands ภาษาไทย

ภาษาไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা ভাষার

বাংলা ভাষার Dansk

Dansk Suomi

Suomi हिन्दी

हिन्दी Pilipino

Pilipino Türkçe

Türkçe Gaeilge

Gaeilge العربية

العربية Indonesia

Indonesia Norsk

Norsk تمل

تمل český

český ελληνικά

ελληνικά український

український Javanese

Javanese فارسی

فارسی தமிழ்

தமிழ் తెలుగు

తెలుగు नेपाली

नेपाली Burmese

Burmese български

български ລາວ

ລາວ Latine

Latine Қазақша

Қазақша Euskal

Euskal Azərbaycan

Azərbaycan Slovenský jazyk

Slovenský jazyk Македонски

Македонски Lietuvos

Lietuvos Eesti Keel

Eesti Keel Română

Română Slovenski

Slovenski मराठी

मराठी Srpski језик

Srpski језик

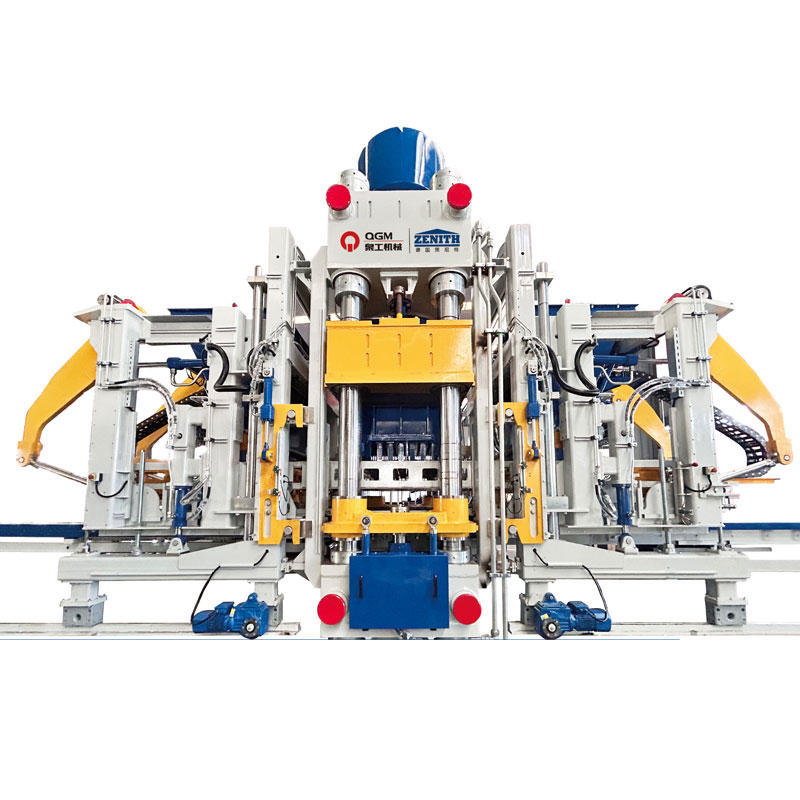

Hollow Block Mould

Send Inquiry

You can rest assured to buy customized Hollow Block Mould from us. Hollow block moulds are made of high quality wear-resistant steel. Through the wire cutting process, the gap between the upper and lower sides of the mould is reasonable, clearance 0.8-1mm, which make the mould strong and durable. The integrated heat treatment process makes the moulds more wear-resistant and durable. According to the requirements of different customers, it can provide a variety of specifications and designs. The mould adopts flexible design, according to customer needs, the mould core, pressure plate can be freely replaced, also we provide welding, modular thread locking design and manufacture.

For superstructure moulds in various designs, ZENITH is the benchmark in terms of reliability and product diversity. It is here where our strengths and skills in both craftsmanship and modern CNC- technology have the maximum positive impact on the value of our moulds.

Hollow block moulds Design:

A) MOULD DESIGN WELDED

High quality wear resistant steel

Shoe clearance 0,5-0,8 mm

Holding web thicknesses screwed and therefore changeable

Changeable shoes with inner pots on the tamper head

Robust and proven design

Optimal exploitation of the mould

Optional withdraw sheet design

Cost-effective production

Traditional and proven design

B) SCREWED MOULD DESIGN

Flexible design of mould Shoe clearance 0,5-0,8 mm

Holding web thicknesses and insets screwed

Changeable shoes with inner pots on the tamper head

Stress-free construction

Optional withdraw sheet design

nterior parts feasible in nitrated(62-68 HRC) version

Based on customer requirements, we can also supply the combination of a welding and modular threaded connection design.