English

English  Esperanto

Esperanto Afrikaans

Afrikaans Català

Català שפה עברית

שפה עברית Cymraeg

Cymraeg Galego

Galego Latviešu

Latviešu icelandic

icelandic ייִדיש

ייִדיש беларускі

беларускі Hrvatski

Hrvatski Kreyòl ayisyen

Kreyòl ayisyen Shqiptar

Shqiptar Malti

Malti lugha ya Kiswahili

lugha ya Kiswahili አማርኛ

አማርኛ Bosanski

Bosanski Frysk

Frysk ភាសាខ្មែរ

ភាសាខ្មែរ ქართული

ქართული ગુજરાતી

ગુજરાતી Hausa

Hausa Кыргыз тили

Кыргыз тили ಕನ್ನಡ

ಕನ್ನಡ Corsa

Corsa Kurdî

Kurdî മലയാളം

മലയാളം Maori

Maori Монгол хэл

Монгол хэл Hmong

Hmong IsiXhosa

IsiXhosa Zulu

Zulu Punjabi

Punjabi پښتو

پښتو Chichewa

Chichewa Samoa

Samoa Sesotho

Sesotho සිංහල

සිංහල Gàidhlig

Gàidhlig Cebuano

Cebuano Somali

Somali Тоҷикӣ

Тоҷикӣ O'zbek

O'zbek Hawaiian

Hawaiian سنڌي

سنڌي Shinra

Shinra Հայերեն

Հայերեն Igbo

Igbo Sundanese

Sundanese Lëtzebuergesch

Lëtzebuergesch Malagasy

Malagasy Yoruba

Yoruba অসমীয়া

অসমীয়া ଓଡିଆ

ଓଡିଆ Español

Español Português

Português русский

русский Français

Français 日本語

日本語 Deutsch

Deutsch tiếng Việt

tiếng Việt Italiano

Italiano Nederlands

Nederlands ภาษาไทย

ภาษาไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা ভাষার

বাংলা ভাষার Dansk

Dansk Suomi

Suomi हिन्दी

हिन्दी Pilipino

Pilipino Türkçe

Türkçe Gaeilge

Gaeilge العربية

العربية Indonesia

Indonesia Norsk

Norsk تمل

تمل český

český ελληνικά

ελληνικά український

український Javanese

Javanese فارسی

فارسی தமிழ்

தமிழ் తెలుగు

తెలుగు नेपाली

नेपाली Burmese

Burmese български

български ລາວ

ລາວ Latine

Latine Қазақша

Қазақша Euskal

Euskal Azərbaycan

Azərbaycan Slovenský jazyk

Slovenský jazyk Македонски

Македонски Lietuvos

Lietuvos Eesti Keel

Eesti Keel Română

Română Slovenski

Slovenski मराठी

मराठी Srpski језик

Srpski језик

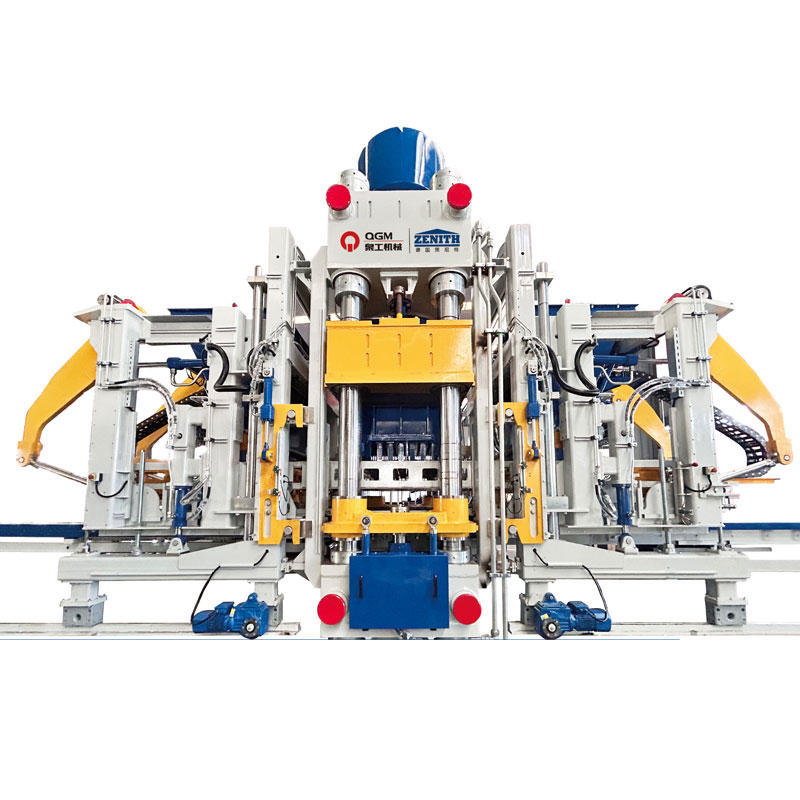

Zenith 913 Brick Laying Machine

Send Inquiry

Main Technology Features

1)Manual control mode: The equipment operation can be controlled by manual mode through operating directional control valve. The directional control valve consists of two modules: direction control rod and integrated instruction button, with precise control, convenient operation and strong maneuverability.

2)Full-automation mode: The block machine is also equipped with automatic controller specially used for mobile block making machine. Operators can easily operate the equipment via dialogic and visual colored display screen to realize automatic production.

3)Frequency conversion control: The motor of this equipment adopts frequency conversion control system, featuring with low energy consumption and stable operating. This control system has prec pressure control capability. The frequency conversion controlled electric drive unit can ensure rapid and smooth moving of the equipment, increasing efficiency and decreasing cost.

4)Rapid mould replacing: The machine sets a series of mould coefficient criterion through this system. This mould replacing system has functions of mechanical fast locking, fast replacing of mould a tamper head, electronic controlled height of feeding device, etc., which ensures that various moulds can be replaced at the fastest speed.

5)Rapid disassembly of protective net: The telescopic spring is installed on the protective net with quick installation and disassembly. It is convenient to clean and maintain the mould. The firm and easy locking mode can guarantee the maximum safety of the operator while providing convenience.

Technical Data

| Features | |

| Hopper volume | 1,000L |

| Max.feeding height of the loader | 2,005L |

| Max forming length | 1,240mm |

| Max.foming width | 1,130mm |

| Min product height | 175mm |

| Max. product height | 330mm |

| Weight | |

| Including mould and vibration motor | 5T |

| Size | |

| Total lengthi | 2,850mm |

| Total height | 3,000mm |

| Total width | 2,337mm |

| Vibration system | |

| Max exciting force of vibration table | 48KN |

| Max.exciting force of upper vibration | 20KN |

| Energy consumption | |

| With maximum numbers of vibration motor | 16KW |

Zenith 913 Machine Layout

Production Capacity

| Block Type | Dimension(mm) | Pictures | Qty/Cycle | Cycle Time | Production Capacity(Per 8hs) |

| Hollow Block | 400*200*200 |

|

12 | 35s | 9,792pcs |

| 400*150*200 | 16 | 35s | 13,165pcs | ||

| 520*160*200 | 12 | 35s | 9,792pcs | ||

| Soild Block | 225*112.5*80 |

|

12 | 35s | 9,792pcs |