English

English  Esperanto

Esperanto Afrikaans

Afrikaans Català

Català שפה עברית

שפה עברית Cymraeg

Cymraeg Galego

Galego Latviešu

Latviešu icelandic

icelandic ייִדיש

ייִדיש беларускі

беларускі Hrvatski

Hrvatski Kreyòl ayisyen

Kreyòl ayisyen Shqiptar

Shqiptar Malti

Malti lugha ya Kiswahili

lugha ya Kiswahili አማርኛ

አማርኛ Bosanski

Bosanski Frysk

Frysk ភាសាខ្មែរ

ភាសាខ្មែរ ქართული

ქართული ગુજરાતી

ગુજરાતી Hausa

Hausa Кыргыз тили

Кыргыз тили ಕನ್ನಡ

ಕನ್ನಡ Corsa

Corsa Kurdî

Kurdî മലയാളം

മലയാളം Maori

Maori Монгол хэл

Монгол хэл Hmong

Hmong IsiXhosa

IsiXhosa Zulu

Zulu Punjabi

Punjabi پښتو

پښتو Chichewa

Chichewa Samoa

Samoa Sesotho

Sesotho සිංහල

සිංහල Gàidhlig

Gàidhlig Cebuano

Cebuano Somali

Somali Тоҷикӣ

Тоҷикӣ O'zbek

O'zbek Hawaiian

Hawaiian سنڌي

سنڌي Shinra

Shinra Հայերեն

Հայերեն Igbo

Igbo Sundanese

Sundanese Lëtzebuergesch

Lëtzebuergesch Malagasy

Malagasy Yoruba

Yoruba অসমীয়া

অসমীয়া ଓଡିଆ

ଓଡିଆ Español

Español Português

Português русский

русский Français

Français 日本語

日本語 Deutsch

Deutsch tiếng Việt

tiếng Việt Italiano

Italiano Nederlands

Nederlands ภาษาไทย

ภาษาไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা ভাষার

বাংলা ভাষার Dansk

Dansk Suomi

Suomi हिन्दी

हिन्दी Pilipino

Pilipino Türkçe

Türkçe Gaeilge

Gaeilge العربية

العربية Indonesia

Indonesia Norsk

Norsk تمل

تمل český

český ελληνικά

ελληνικά український

український Javanese

Javanese فارسی

فارسی தமிழ்

தமிழ் తెలుగు

తెలుగు नेपाली

नेपाली Burmese

Burmese български

български ລາວ

ລາວ Latine

Latine Қазақша

Қазақша Euskal

Euskal Azərbaycan

Azərbaycan Slovenský jazyk

Slovenský jazyk Македонски

Македонски Lietuvos

Lietuvos Eesti Keel

Eesti Keel Română

Română Slovenski

Slovenski मराठी

मराठी Srpski језик

Srpski језик

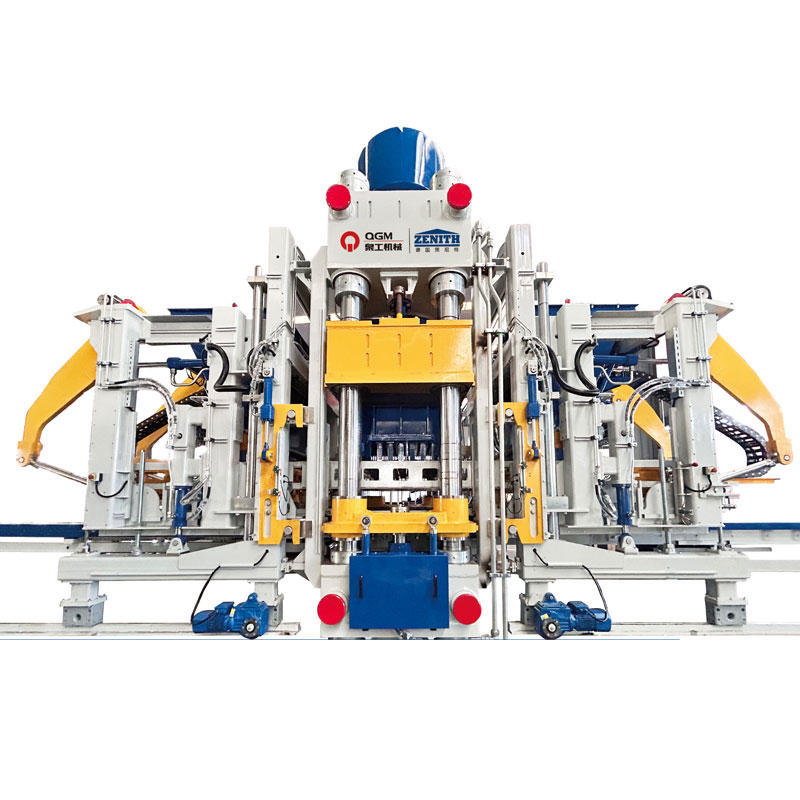

Zenith 940SC Pallet-Free Block Machine

Send Inquiry

Main Technology Features

1)The self-explanatory, menu-driven Touch Panel makes the machine operation very easy. The production parameters for different mould types and production programmes are entered and saved by using the well-arranged menu masks. A quick Siemens SPS is used for intenal signal processing.

2)High-eifficiency Hydraulic System. Hydraulic power uses two-circuilt high pressure; Hydraulic system with two Milti-Star- Piston Pumps. It uses proportional hydraulic technology to adjust the speed and working according to the different products produced. hydraulic movements can be driven simultaneously and independently with different speeds and pressures and all data can be setting in the touch screen. All the information like time, calculation, option, hydraulic speed and pressure can be set up through touch screen.

3)High-eifficiency Vibration system. The vibration table is designed in order to have four different production levels; The upper part of the vibration table is two-parted in order to achieve an even power transmission and an optimum compaction; Replaceable wear plate for protection of upper parts of vibration table: The vibration table for acceptance of two vibrators to achieve a maximum centrifugal force of 80 kN; to produce 50cm high blocks, the mold frame is equipped with vibrators. (Can be equipped with 2, 4, 6. 8 vibrators according to the block height), Vibration motors uses Servo motors.

4) Aggregate Feeding system. Feeder with hydraulic driven; can adjust feeder box runs on changeable ant torque high precision rail according to different molds, feeder guide wheel diameter Ø 80mm; Hydraulic driven swivel scraper(three-parted) for proper cleaning of the mould surface; The hydraulically driven distribution grate is leading to a even distribution of the concrete in the mould; Height adjustable cleaning brush, attached to the front wall of the feed drawer for cleaning of tamper head shoes...

Technical Data

| Base material hopper | 1,200L |

| Base material feedbox | 2,000L |

| Pigment hopper | 800L |

| Pigment feedbox | 2,000L |

| Max.feeding height of loader | 2,800mm |

| Forming size | |

| Max forming length | 1240mm |

| Max foming width(producing on the vibration table) | 1.000mm |

| Max foming width(producing on the ground) | 1,240mm |

| Product height | |

| Multi-layer production | |

| Min.product height(producing on the pallet) | 50mm |

| Max. product height | 250mm |

| Max stacking heightpallet height of one layer product) | 640mm |

| Low level production on the pallet | |

| Max product height | 600mm |

| Low level production on the floor | |

| Max.product height | 650mm |

| Production on the floor | |

| Max. product height | 1.000mm |

| Min product height | 250mm |

| Machine weight | |

| Without mould and pigments device | 11.7T |

| Pigment device | 1.7T |

| Machine size | |

| Total length(without pigment device) | 4,400mm |

| Total length(with pigment device) | 6,380mm |

| Max. total height | 3,700mm |

| Min total heigh(ransport height) | 3,240mm |

| Total widh(ncluding control panel) | 2.540mm |

| Vibration system | |

| Max. exciting force of the vibration fable | 80KN |

| Min. excting force of the top vibration | 40KN |

| Energy consumption | |

| Based on the maximum number of vibrating table | 42KW |

Production Capacity

| Block Type | Dimension (mm) | Pictures | aty/Cycle | Cycle Time | Production Capacity (Per 8hs) |

| Hollow Block | 400*200*200 |

|

12 | 40s | 8,640 pcs |

| Rectangular Paver | 200* 100*60 |

|

54 | 38s | 817m2 |

| Rectangular Paver (without facemix) | 200*100*60 |

|

54 | 36s | 864m2 |

| UNI Pavers | 225*112.5*60-80 |

|

40 | 38s | 757m2 |

| Curstone | 150*1000*300 |

|

4 | 46s | 2,504 pcs |