English

English  Esperanto

Esperanto Afrikaans

Afrikaans Català

Català שפה עברית

שפה עברית Cymraeg

Cymraeg Galego

Galego Latviešu

Latviešu icelandic

icelandic ייִדיש

ייִדיש беларускі

беларускі Hrvatski

Hrvatski Kreyòl ayisyen

Kreyòl ayisyen Shqiptar

Shqiptar Malti

Malti lugha ya Kiswahili

lugha ya Kiswahili አማርኛ

አማርኛ Bosanski

Bosanski Frysk

Frysk ភាសាខ្មែរ

ភាសាខ្មែរ ქართული

ქართული ગુજરાતી

ગુજરાતી Hausa

Hausa Кыргыз тили

Кыргыз тили ಕನ್ನಡ

ಕನ್ನಡ Corsa

Corsa Kurdî

Kurdî മലയാളം

മലയാളം Maori

Maori Монгол хэл

Монгол хэл Hmong

Hmong IsiXhosa

IsiXhosa Zulu

Zulu Punjabi

Punjabi پښتو

پښتو Chichewa

Chichewa Samoa

Samoa Sesotho

Sesotho සිංහල

සිංහල Gàidhlig

Gàidhlig Cebuano

Cebuano Somali

Somali Тоҷикӣ

Тоҷикӣ O'zbek

O'zbek Hawaiian

Hawaiian سنڌي

سنڌي Shinra

Shinra Հայերեն

Հայերեն Igbo

Igbo Sundanese

Sundanese Lëtzebuergesch

Lëtzebuergesch Malagasy

Malagasy Yoruba

Yoruba অসমীয়া

অসমীয়া ଓଡିଆ

ଓଡିଆ Español

Español Português

Português русский

русский Français

Français 日本語

日本語 Deutsch

Deutsch tiếng Việt

tiếng Việt Italiano

Italiano Nederlands

Nederlands ภาษาไทย

ภาษาไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা ভাষার

বাংলা ভাষার Dansk

Dansk Suomi

Suomi हिन्दी

हिन्दी Pilipino

Pilipino Türkçe

Türkçe Gaeilge

Gaeilge العربية

العربية Indonesia

Indonesia Norsk

Norsk تمل

تمل český

český ελληνικά

ελληνικά український

український Javanese

Javanese فارسی

فارسی தமிழ்

தமிழ் తెలుగు

తెలుగు नेपाली

नेपाली Burmese

Burmese български

български ລາວ

ລາວ Latine

Latine Қазақша

Қазақша Euskal

Euskal Azərbaycan

Azərbaycan Slovenský jazyk

Slovenský jazyk Македонски

Македонски Lietuvos

Lietuvos Eesti Keel

Eesti Keel Română

Română Slovenski

Slovenski मराठी

मराठी Srpski језик

Srpski језик

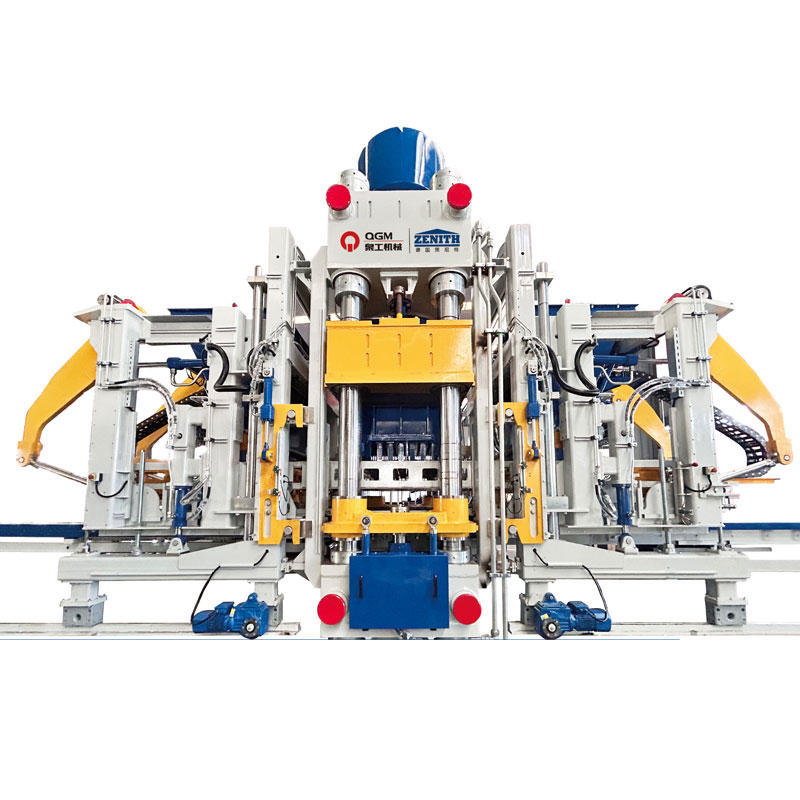

HP-1200T Hermetic Press Machine

Send Inquiry

You can rest assured to buy HP-1200T Hermetic Press Machine from our factory.Block making machines are mechanical equipment that use fly ash, crushed construction waste, crushed stone, stone powder, etc. as raw materials to produce environmentally friendly new materials such as blocks and cement bricks. New wall materials are mainly blocks and cement bricks. Block making machines are available in different sizes and models, and are able to produce bricks of different shapes and sizes according to their specifications. The main components of a block making machine include a hopper, a mixing drum or pan, a mold, and a conveyor belt or stacking system. Raw materials such as cement, sand and water are mixed in the hopper and poured into the mixing drum. The mixed material is then fed into a mold and compressed under high pressure and vibration to form a shape.

Seven-station cycle brick making

1. Fabric unloading station

2. Fabric dispersing station

3. Maintenance station (mold changing station)

4. Bottom material unloading station

5. Pre-pressing station

6. Main pressing station

7. Demolding station

Technical description

1. The main pressure of the HP-1200T Hermetic Press Machine adopts a large-diameter transition oil tank filling device, which can respond quickly, move sensitively, and can output tons of pressure.

2. The hydraulic station adopts a variable pump, which adjusts the speed and pressure through a proportional valve, which is energy-saving and easy to operate.

3. The turntable adopts an ultra-large slewing bearing, which is controlled by a servo motor with an encoder, with stable operation and precise control.

4. The HP-1200T Hermetic Press Machine adopts an advanced visual control system, and the PLC adopts the Siemens S7-1500 series.

5. The fabric unloading device has a built-in planetary mixer and uses a quantitative turntable for unloading. The unloading amount is accurate and stable each time.

6. The bottom material unloading device of the HP-1200T Hermetic Press Machine can quantitatively unload the bottom material through a variety of transition devices, thereby controlling the height of the finished bricks, greatly saving the number of molds.

Equipment parameters

| Model | HP-1200T |

| Number of Workstations | 7 |

| Brick-like arrangement (listing) | 900*900 (1 piece/board) |

| 500*500 (2 pieces/board) | |

| 400*400 (4 pieces/board) | |

| Maximum brick thickness | 80mm |

| Maximum main pressure | 1200t |

| Diameter of main pressure cylinder | 740mm |

| Weight (including one set of molds) | About 90,000kg |

| Power of main machine | 132.08KW |

| Cycle cycle | 12-18s |

| Length, width and height | 9000*7500*4000mm |