English

English  Esperanto

Esperanto Afrikaans

Afrikaans Català

Català שפה עברית

שפה עברית Cymraeg

Cymraeg Galego

Galego Latviešu

Latviešu icelandic

icelandic ייִדיש

ייִדיש беларускі

беларускі Hrvatski

Hrvatski Kreyòl ayisyen

Kreyòl ayisyen Shqiptar

Shqiptar Malti

Malti lugha ya Kiswahili

lugha ya Kiswahili አማርኛ

አማርኛ Bosanski

Bosanski Frysk

Frysk ភាសាខ្មែរ

ភាសាខ្មែរ ქართული

ქართული ગુજરાતી

ગુજરાતી Hausa

Hausa Кыргыз тили

Кыргыз тили ಕನ್ನಡ

ಕನ್ನಡ Corsa

Corsa Kurdî

Kurdî മലയാളം

മലയാളം Maori

Maori Монгол хэл

Монгол хэл Hmong

Hmong IsiXhosa

IsiXhosa Zulu

Zulu Punjabi

Punjabi پښتو

پښتو Chichewa

Chichewa Samoa

Samoa Sesotho

Sesotho සිංහල

සිංහල Gàidhlig

Gàidhlig Cebuano

Cebuano Somali

Somali Тоҷикӣ

Тоҷикӣ O'zbek

O'zbek Hawaiian

Hawaiian سنڌي

سنڌي Shinra

Shinra Հայերեն

Հայերեն Igbo

Igbo Sundanese

Sundanese Lëtzebuergesch

Lëtzebuergesch Malagasy

Malagasy Yoruba

Yoruba অসমীয়া

অসমীয়া ଓଡିଆ

ଓଡିଆ Español

Español Português

Português русский

русский Français

Français 日本語

日本語 Deutsch

Deutsch tiếng Việt

tiếng Việt Italiano

Italiano Nederlands

Nederlands ภาษาไทย

ภาษาไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা ভাষার

বাংলা ভাষার Dansk

Dansk Suomi

Suomi हिन्दी

हिन्दी Pilipino

Pilipino Türkçe

Türkçe Gaeilge

Gaeilge العربية

العربية Indonesia

Indonesia Norsk

Norsk تمل

تمل český

český ελληνικά

ελληνικά український

український Javanese

Javanese فارسی

فارسی தமிழ்

தமிழ் తెలుగు

తెలుగు नेपाली

नेपाली Burmese

Burmese български

български ລາວ

ລາວ Latine

Latine Қазақша

Қазақша Euskal

Euskal Azərbaycan

Azərbaycan Slovenský jazyk

Slovenský jazyk Македонски

Македонски Lietuvos

Lietuvos Eesti Keel

Eesti Keel Română

Română Slovenski

Slovenski मराठी

मराठी Srpski језик

Srpski језик

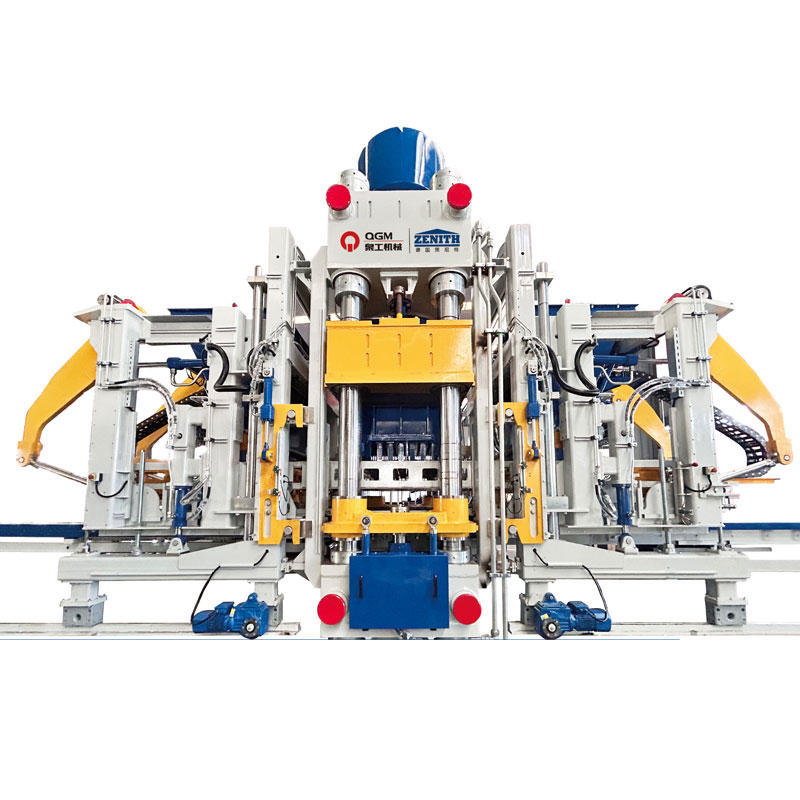

HP-600T/800T Hermetic Press Machine

Send Inquiry

High quality HP-600T/800T Hermetic Press Machine is offered by China manufacturer Quangong Machinery Co., Ltd. The fully automatic imitation stone PC brick machine and its production line adopt high-pressure hydraulic molding, complete the filter-pressing molding of cement aggregates through pressure, and use advanced PLC program control circuit to control the whole process of the machine. HP-600T/800T Hermetic Press Machine improves the production efficiency of the machine, improves product quality, is easy to operate and has low production cost. It is an advanced PC brick production equipment.

The production line completes the formula matching through the batching and mixing system, and the conveyor belt and lifting bucket are used to mix in the mixer, and the mixed material is transported to the fabric mixer. The main slide of the HP-600T/800T Hermetic Press Machine slides out. When the fabric is unloaded, the material is lowered into the mold frame of the slide through the quantitative bucket. The slide slides to the bottom of the frame for filter-pressing molding. The pallet is sent to another station of the slide through the plate feeder, and the demoulding is completed when the fabric is quantitatively unloaded. The delivery of the pallet and the stacking of the plate (with wet bricks) are completed during pressure molding.

Equipment parameters

| Model | HP-600T |

| Number of Workstation | 1 |

| Brick sample specifications | 1200*600 (1 piece/plate) |

| Brick thickness | 20-50mm |

| Maximum main pressure | 600T |

| Diameter of main pressure cylinder | 650mm |

| Stroke of main pressure cylinder | 200mm |

| Weight | About 15,000kg |

| Power of main machine | 28KW |

| Cycle cycle | 40s |

| Length, width and height | 2500*2100*2300mm |

| Model | HP-800T |

| Number of Workstation | 1 |

| Brick sample specifications | 1200*800 (1 piece/plate) |

| Brick thickness | 20-50mm |

| Maximum main pressure | 800T |

| Diameter of main pressure cylinder | 420mm*2 |

| Stroke of main pressure cylinder | 200mm |

| Weight | About 22,000kg |

| Power of main machine | 30KW |

| Cycle cycle | 45s |

| Length, width and height | 4000*3000*2300mm |