English

English  Esperanto

Esperanto Afrikaans

Afrikaans Català

Català שפה עברית

שפה עברית Cymraeg

Cymraeg Galego

Galego Latviešu

Latviešu icelandic

icelandic ייִדיש

ייִדיש беларускі

беларускі Hrvatski

Hrvatski Kreyòl ayisyen

Kreyòl ayisyen Shqiptar

Shqiptar Malti

Malti lugha ya Kiswahili

lugha ya Kiswahili አማርኛ

አማርኛ Bosanski

Bosanski Frysk

Frysk ភាសាខ្មែរ

ភាសាខ្មែរ ქართული

ქართული ગુજરાતી

ગુજરાતી Hausa

Hausa Кыргыз тили

Кыргыз тили ಕನ್ನಡ

ಕನ್ನಡ Corsa

Corsa Kurdî

Kurdî മലയാളം

മലയാളം Maori

Maori Монгол хэл

Монгол хэл Hmong

Hmong IsiXhosa

IsiXhosa Zulu

Zulu Punjabi

Punjabi پښتو

پښتو Chichewa

Chichewa Samoa

Samoa Sesotho

Sesotho සිංහල

සිංහල Gàidhlig

Gàidhlig Cebuano

Cebuano Somali

Somali Тоҷикӣ

Тоҷикӣ O'zbek

O'zbek Hawaiian

Hawaiian سنڌي

سنڌي Shinra

Shinra Հայերեն

Հայերեն Igbo

Igbo Sundanese

Sundanese Lëtzebuergesch

Lëtzebuergesch Malagasy

Malagasy Yoruba

Yoruba অসমীয়া

অসমীয়া ଓଡିଆ

ଓଡିଆ Español

Español Português

Português русский

русский Français

Français 日本語

日本語 Deutsch

Deutsch tiếng Việt

tiếng Việt Italiano

Italiano Nederlands

Nederlands ภาษาไทย

ภาษาไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা ভাষার

বাংলা ভাষার Dansk

Dansk Suomi

Suomi हिन्दी

हिन्दी Pilipino

Pilipino Türkçe

Türkçe Gaeilge

Gaeilge العربية

العربية Indonesia

Indonesia Norsk

Norsk تمل

تمل český

český ελληνικά

ελληνικά український

український Javanese

Javanese فارسی

فارسی தமிழ்

தமிழ் తెలుగు

తెలుగు नेपाली

नेपाली Burmese

Burmese български

български ລາວ

ລາວ Latine

Latine Қазақша

Қазақша Euskal

Euskal Azərbaycan

Azərbaycan Slovenský jazyk

Slovenský jazyk Македонски

Македонски Lietuvos

Lietuvos Eesti Keel

Eesti Keel Română

Română Slovenski

Slovenski मराठी

मराठी Srpski језик

Srpski језик

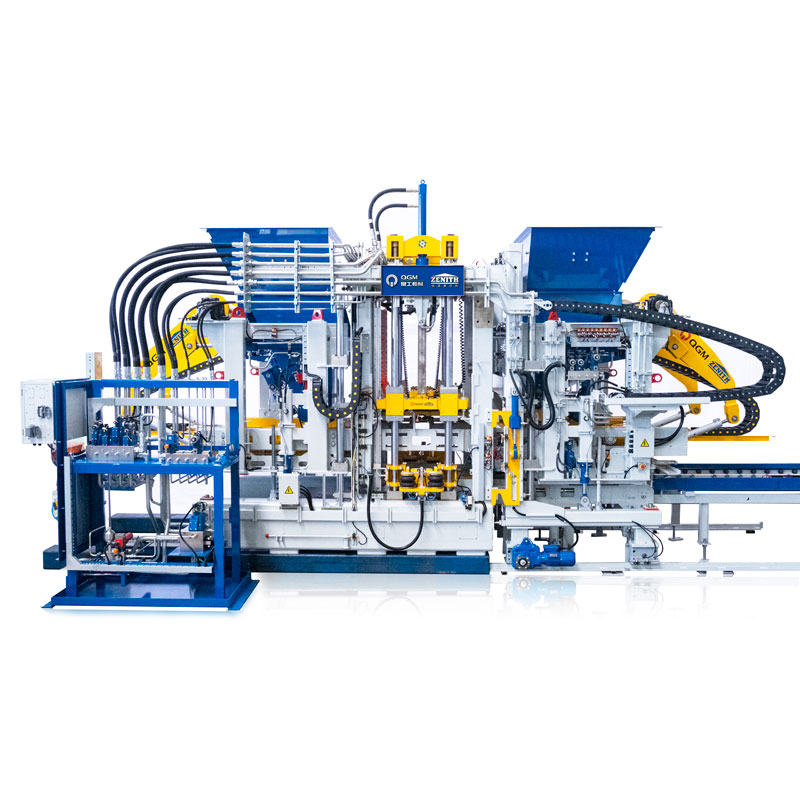

China Construction waste brick making machine Manufacturer, Supplier, Factory

Being supported by an highly developed and specialist IT team, we could give technical support on pre-sales & after-sales service for Construction waste brick making machine,Cement brick machine production line,Fully automatic no-burning brick machine production line,Fully automatic brick making machine,Fully automatic brick making machine production line, Let's cooperate hand in hand to jointly make a beautiful upcoming. We sincerely welcome you to pay a visit to our company or speak to us for cooperation!

Construction waste brick making machine, We care about every steps of our services, from factory selection, product development & design, price negotiation, inspection, shipping to aftermarket. We have implemented a strict and complete quality control system, which ensures that each product can meet quality requirements of customers. Besides, all of our products have been strictly inspected before shipment. Your Success, Our Glory: Our aim is to help customers realize their goals. We are making great efforts to achieve this win-win situation and sincerely welcome you to join us.

Hot Products

Automatic Pallet Feeding Brick Machine

You can rest assured to buy Automatic Pallet Feeding Brick Machine from our factory. This type of machine can produce a wide range of bricks, including bricks used in construction, for landscaping purposes, and paving.HP-250T/600T Hermetic Press Machine

You can rest assured to buy HP-250T/600T Hermetic Press Machine from our factory.These slabs are used as terrace or paving slabs, and the large-format slabs for public squares and buildings (central stations, airports, shopping malls, etc).QT6 Cement Block Making Machine

You can rest assured to buy QT6 Cement Block Making Machine from our factory. QT6 is an automatic block machine with the features of cost-effective and good performance. Same as QT10, both of them are designed and produce by QGM independently. Also it can be widely used in municipal engineering, building work and garden construction. Raw materials: Crushed stone, sand, cement, dust and coal fly ash, cinder, slag, gangue, gravel, perlite, and other industrial wastes.Grass Stone Mould

As the professional grass stone mould manufacturer, QGM Grass Stone Mould adopts low carbon alloy high strength carburizing steel,clearance 0.5- 0.6mm, the suspension plate adopts imported wear-resistant high-strengthstructural steel, which is durable and not easy to wear.ZN1000C Concrete Block Machine

You can rest assured to buy ZN1000C Concrete Block Machine from our factory. ZN1000C automatic block making production line with the central control system, the customer is able to guarantee the quality of blocks and service in accordance with the standards and requirements of different projects. It could produce around 800 m2 quality paving blocks per day(8 hours) which can enhance their competitiveness in the industry.Fully Automatic Production Line

As the professional manufacturer, we would like to provide you Fully Automatic Production Line. The fully automated block machine is a sophisticated piece of equipment that utilizes a variety of materials, including slag, fly ash, stone powder, sand, gravel, cement, and more, to produce high-pressure blocks or bricks. The machine's classic vibration mode is ideally suited for manufacturing high-strength blocks and standard bricks.