English

English  Esperanto

Esperanto Afrikaans

Afrikaans Català

Català שפה עברית

שפה עברית Cymraeg

Cymraeg Galego

Galego Latviešu

Latviešu icelandic

icelandic ייִדיש

ייִדיש беларускі

беларускі Hrvatski

Hrvatski Kreyòl ayisyen

Kreyòl ayisyen Shqiptar

Shqiptar Malti

Malti lugha ya Kiswahili

lugha ya Kiswahili አማርኛ

አማርኛ Bosanski

Bosanski Frysk

Frysk ភាសាខ្មែរ

ភាសាខ្មែរ ქართული

ქართული ગુજરાતી

ગુજરાતી Hausa

Hausa Кыргыз тили

Кыргыз тили ಕನ್ನಡ

ಕನ್ನಡ Corsa

Corsa Kurdî

Kurdî മലയാളം

മലയാളം Maori

Maori Монгол хэл

Монгол хэл Hmong

Hmong IsiXhosa

IsiXhosa Zulu

Zulu Punjabi

Punjabi پښتو

پښتو Chichewa

Chichewa Samoa

Samoa Sesotho

Sesotho සිංහල

සිංහල Gàidhlig

Gàidhlig Cebuano

Cebuano Somali

Somali Тоҷикӣ

Тоҷикӣ O'zbek

O'zbek Hawaiian

Hawaiian سنڌي

سنڌي Shinra

Shinra Հայերեն

Հայերեն Igbo

Igbo Sundanese

Sundanese Lëtzebuergesch

Lëtzebuergesch Malagasy

Malagasy Yoruba

Yoruba অসমীয়া

অসমীয়া ଓଡିଆ

ଓଡିଆ Español

Español Português

Português русский

русский Français

Français 日本語

日本語 Deutsch

Deutsch tiếng Việt

tiếng Việt Italiano

Italiano Nederlands

Nederlands ภาษาไทย

ภาษาไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা ভাষার

বাংলা ভাষার Dansk

Dansk Suomi

Suomi हिन्दी

हिन्दी Pilipino

Pilipino Türkçe

Türkçe Gaeilge

Gaeilge العربية

العربية Indonesia

Indonesia Norsk

Norsk تمل

تمل český

český ελληνικά

ελληνικά український

український Javanese

Javanese فارسی

فارسی தமிழ்

தமிழ் తెలుగు

తెలుగు नेपाली

नेपाली Burmese

Burmese български

български ລາວ

ລາວ Latine

Latine Қазақша

Қазақша Euskal

Euskal Azərbaycan

Azərbaycan Slovenský jazyk

Slovenský jazyk Македонски

Македонски Lietuvos

Lietuvos Eesti Keel

Eesti Keel Română

Română Slovenski

Slovenski मराठी

मराठी Srpski језик

Srpski језик

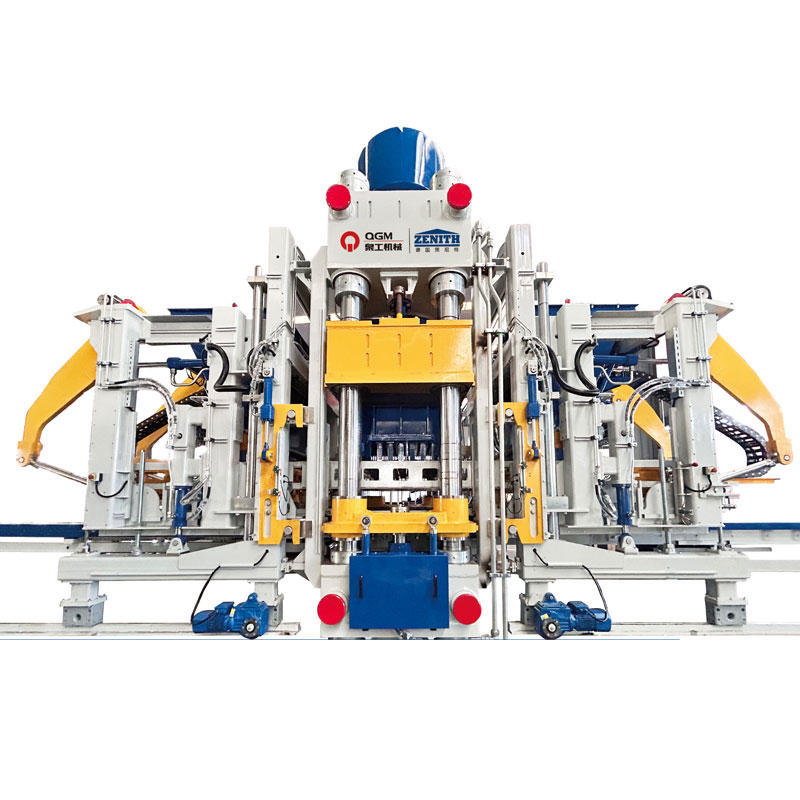

Vertical Brick Machine Mixer

Send Inquiry

Vertical Brick Machine Mixer(JN-350)

You can rest assured to buy customized Vertical Brick Machine Mixer from us. Vertical Brick Machine Mixer is mainly used to mix raw materials like sand, cement, water, and different additives like flyl ash, lime, and gypsum to produce a uniform mix that is then fed into the brick machine for molding.The mixer typicallyl consists of a large drum or container with multiple blades or paddles that rotate to mix the materials thoroughly. Some vertical brick machine mixers also include a control system that allows the operator to adjust mixing time, speed, and other parameters to ensure optimal mixing quality.Vertical brick machine mixers are widely used in the brick making industry, especially for producing bricks made of concrete, clay, or cement. They can also be used to mix other materials for construction purposes or in other industries that require a uniform mix of different materials.

Twin Shaft Mixer(JS-750)

Twin Shaft Mixer is a type of mixer that has two horizontal shafts continuously agitating the concrete mixture. It is often used in large-scale construction projects as it can handle large volumes of concrete and also has a fast mixing time. The two shafts in this mixer rotate in opposite directions, which ensures that the concrete is thoroughly mixed. The blades on the shaft are designed to move the concrete from the center of the mixer to the sides in a corkscrew fashion, ensuring that the entire batch is mixed evenly. The Twin Shaft Mixer is preferred over other types of concrete mixers because of its high efficiency, low noise, easy maintenance, and the ability to mix various types of materials, including dry, semi-dry, and plastic concrete.

Twin-shaft mixers are widely used in construction projects like highways, buildings, bridges, tunnels, and airports.

Technical Parameters

| ltem | JN350 | JS500 | JS750 | JS1000 | |

| Discharging capacity() | 350 | 500 | 750 | 1000 | |

| Feeding capacity(l) | 550 | 750 | 1150 | 1500 | |

| Theoretic productivity (m/h) | 12.6 | 25 | 35 | 50 | |

| Maximum diameter of aggregate ( cobble/crushed stone ) (mm) | s30 | s50 | s60 | s60 | |

| Cycle time (s) | 100 | 72 | 72 | 60 | |

| Total weight (kg) | 3500 | 4000 | 5500 | 870 | |

| Dimensions(mm) | Length | 3722 | 4460 | 5025 | 10460 |

| Width | 1370 | 3050 | 3100 | 3400 | |

| Height | 3630 | 2680 | 5680 | 9050 | |

| Mixing-shaft | Rotating Speed(r/min) | 106 | 31 | 31 | 26.5 |

| Quantity | 1*3 | 2*7 | 2*7 | 2*8 | |

| The Power of Mixing Motor(kw) | 7.5 | 18.5 | 30 | 2*18.5 | The Power of Mixing Motor(kw) |

| The Power of Winding Motor (kw) | 4 | 5.5 | 7.5 | 11 | The Power of Winding Motor (kw) |

| The Power of Pump Motor(kw) | 1.1 | 2.2 | 2.2 | 3 | The Power of Pump Motor(kw) |