English

English  Esperanto

Esperanto Afrikaans

Afrikaans Català

Català שפה עברית

שפה עברית Cymraeg

Cymraeg Galego

Galego Latviešu

Latviešu icelandic

icelandic ייִדיש

ייִדיש беларускі

беларускі Hrvatski

Hrvatski Kreyòl ayisyen

Kreyòl ayisyen Shqiptar

Shqiptar Malti

Malti lugha ya Kiswahili

lugha ya Kiswahili አማርኛ

አማርኛ Bosanski

Bosanski Frysk

Frysk ភាសាខ្មែរ

ភាសាខ្មែរ ქართული

ქართული ગુજરાતી

ગુજરાતી Hausa

Hausa Кыргыз тили

Кыргыз тили ಕನ್ನಡ

ಕನ್ನಡ Corsa

Corsa Kurdî

Kurdî മലയാളം

മലയാളം Maori

Maori Монгол хэл

Монгол хэл Hmong

Hmong IsiXhosa

IsiXhosa Zulu

Zulu Punjabi

Punjabi پښتو

پښتو Chichewa

Chichewa Samoa

Samoa Sesotho

Sesotho සිංහල

සිංහල Gàidhlig

Gàidhlig Cebuano

Cebuano Somali

Somali Тоҷикӣ

Тоҷикӣ O'zbek

O'zbek Hawaiian

Hawaiian سنڌي

سنڌي Shinra

Shinra Հայերեն

Հայերեն Igbo

Igbo Sundanese

Sundanese Lëtzebuergesch

Lëtzebuergesch Malagasy

Malagasy Yoruba

Yoruba অসমীয়া

অসমীয়া ଓଡିଆ

ଓଡିଆ Español

Español Português

Português русский

русский Français

Français 日本語

日本語 Deutsch

Deutsch tiếng Việt

tiếng Việt Italiano

Italiano Nederlands

Nederlands ภาษาไทย

ภาษาไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা ভাষার

বাংলা ভাষার Dansk

Dansk Suomi

Suomi हिन्दी

हिन्दी Pilipino

Pilipino Türkçe

Türkçe Gaeilge

Gaeilge العربية

العربية Indonesia

Indonesia Norsk

Norsk تمل

تمل český

český ελληνικά

ελληνικά український

український Javanese

Javanese فارسی

فارسی தமிழ்

தமிழ் తెలుగు

తెలుగు नेपाली

नेपाली Burmese

Burmese български

български ລາວ

ລາວ Latine

Latine Қазақша

Қазақша Euskal

Euskal Azərbaycan

Azərbaycan Slovenský jazyk

Slovenský jazyk Македонски

Македонски Lietuvos

Lietuvos Eesti Keel

Eesti Keel Română

Română Slovenski

Slovenski मराठी

मराठी Srpski језик

Srpski језик

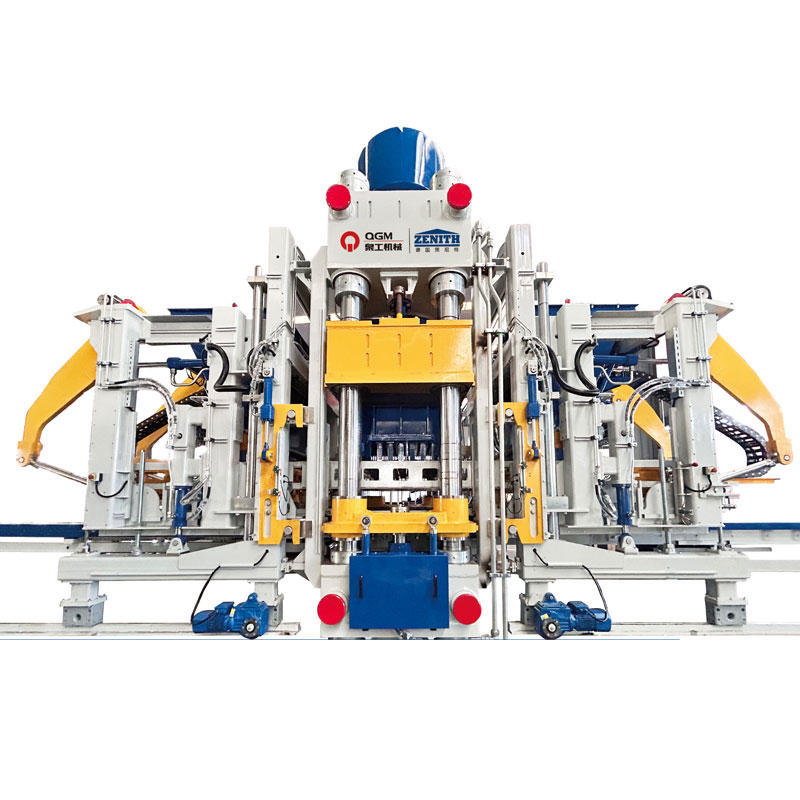

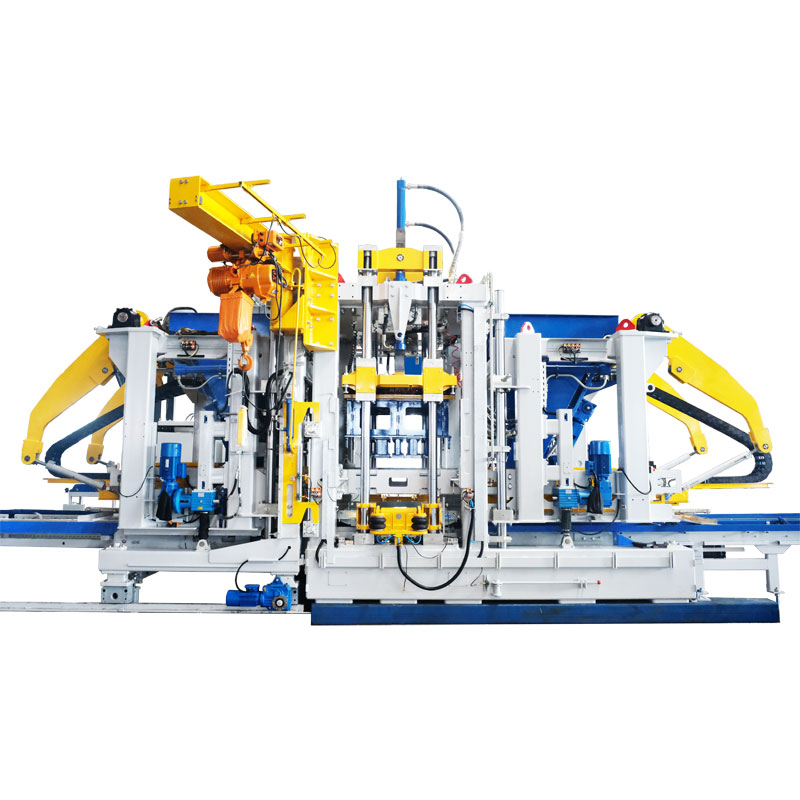

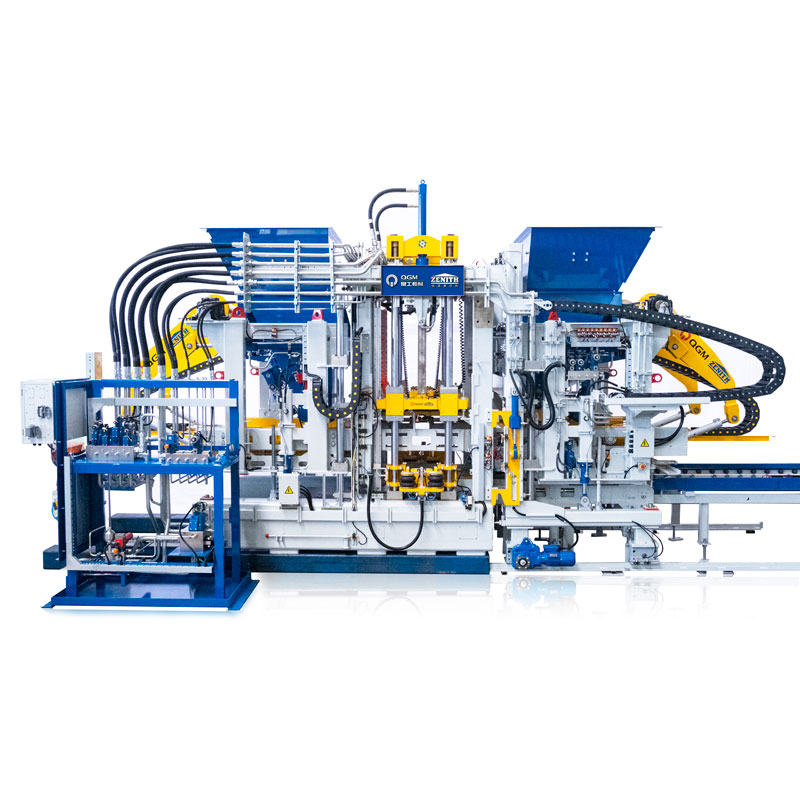

ZN1200S Concrete Block Machine

Send Inquiry

1)The ZN1200S Concrete Block Machine adopts frequency conversion control to reduce the starting current of the motor. This achieves the synchronous operating of vibration assembly and solves the inertia problem motor when stopping, saving power by 20%-30%.

2)With the adoption of Germany Siemens PLC and Siemens touch screen control, the operation is easy, the overall fault is low and operating data can be saved permanently.

3)The hydraulic system is controlled by proportional valve to automatically adjust the flow during production, improving the operating stability and prolonging the service life of the cylinder.

4)The feeding car adopts 360 rotary feeding method with fast speed and uniform distribution, applicable to various raw materials and moulds.

5)After a cabonitriding treatment, the mould is resistant to wear and has a service life of over 50% longer than general moulds.

6)The ZN1200S Concrete Block Machine is equipped with real-time fault diagnosis and alarming system.

7)The vibration table is connected with the workbench and the hole spacing of the eccentric shaft is enlarged, reducing the loss of energy transfer, enlarging the effictive vibration area and improving the vibration efficiency.

Technical Data

| Pallet Size | 1,200*1,150mm |

| Forming Area | 1,100*1,080mm |

| Height of Finished Products | 50-300mm |

| Cycle Time | 15-25s(as per mould) |

| Vibration Force | 120KN |

| Bottom Vibration | 2*15KW(SIEMENS) |

| Top Vibration | 2*0.55KW |

| Power | 70. 35KW |

| Total Weight |

Main Machine:14 98T With facemix device:18.49T |

Production Capacity

| Block Type | Dimension (mm) | Pictures | Qty/Cycle | Production Capacity (Per 8hs) |

| Hollow Block | 390*190*190 |

|

12 | 14,400-16 ,800 pcs |

| Rectangular Paver | 200*100*60-80 |

|

36 | 1,000-1,200m2 |

| Interlocks | 225*112.5*60- -80 |

|

32 | 35,200-38,400pcs |

| Curstone | 500*150*300 |

|

4 | 4,400-5,600 pcs |