English

English  Esperanto

Esperanto Afrikaans

Afrikaans Català

Català שפה עברית

שפה עברית Cymraeg

Cymraeg Galego

Galego Latviešu

Latviešu icelandic

icelandic ייִדיש

ייִדיש беларускі

беларускі Hrvatski

Hrvatski Kreyòl ayisyen

Kreyòl ayisyen Shqiptar

Shqiptar Malti

Malti lugha ya Kiswahili

lugha ya Kiswahili አማርኛ

አማርኛ Bosanski

Bosanski Frysk

Frysk ភាសាខ្មែរ

ភាសាខ្មែរ ქართული

ქართული ગુજરાતી

ગુજરાતી Hausa

Hausa Кыргыз тили

Кыргыз тили ಕನ್ನಡ

ಕನ್ನಡ Corsa

Corsa Kurdî

Kurdî മലയാളം

മലയാളം Maori

Maori Монгол хэл

Монгол хэл Hmong

Hmong IsiXhosa

IsiXhosa Zulu

Zulu Punjabi

Punjabi پښتو

پښتو Chichewa

Chichewa Samoa

Samoa Sesotho

Sesotho සිංහල

සිංහල Gàidhlig

Gàidhlig Cebuano

Cebuano Somali

Somali Тоҷикӣ

Тоҷикӣ O'zbek

O'zbek Hawaiian

Hawaiian سنڌي

سنڌي Shinra

Shinra Հայերեն

Հայերեն Igbo

Igbo Sundanese

Sundanese Lëtzebuergesch

Lëtzebuergesch Malagasy

Malagasy Yoruba

Yoruba অসমীয়া

অসমীয়া ଓଡିଆ

ଓଡିଆ Español

Español Português

Português русский

русский Français

Français 日本語

日本語 Deutsch

Deutsch tiếng Việt

tiếng Việt Italiano

Italiano Nederlands

Nederlands ภาษาไทย

ภาษาไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা ভাষার

বাংলা ভাষার Dansk

Dansk Suomi

Suomi हिन्दी

हिन्दी Pilipino

Pilipino Türkçe

Türkçe Gaeilge

Gaeilge العربية

العربية Indonesia

Indonesia Norsk

Norsk تمل

تمل český

český ελληνικά

ελληνικά український

український Javanese

Javanese فارسی

فارسی தமிழ்

தமிழ் తెలుగు

తెలుగు नेपाली

नेपाली Burmese

Burmese български

български ລາວ

ລາວ Latine

Latine Қазақша

Қазақша Euskal

Euskal Azərbaycan

Azərbaycan Slovenský jazyk

Slovenský jazyk Македонски

Македонски Lietuvos

Lietuvos Eesti Keel

Eesti Keel Română

Română Slovenski

Slovenski मराठी

मराठी Srpski језик

Srpski језик

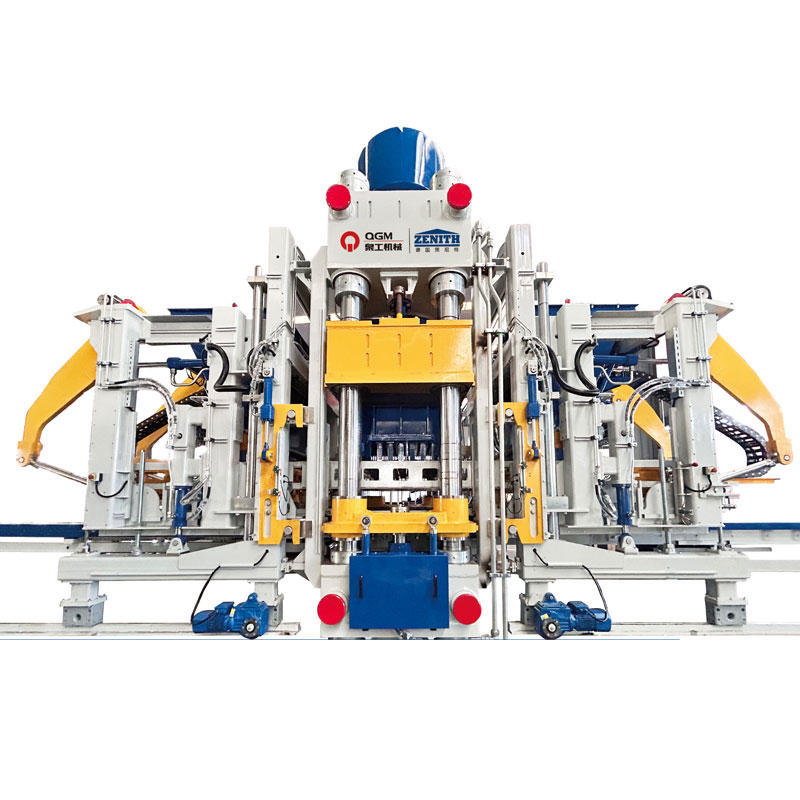

QT10 Concrete Brick Machine

Send Inquiry

Main Technology Features

1、Adopts the most advanced frequency conversional control system from German SIEMENS, plus with the Siemens Touch Screen

A. Visualization screen with easy operation;

B. Able to set up, update and amend the production perimeters, to maximize the production output;

C. Dynamic display of the system's status, automatic troubleshooting, and warning notice;

D. Automatic locking can prevent the production line from mechanical accidents caused by operation mistakes;

E. Troubleshooting via the teleservice.

2、Hydraulic pumps and valves from international brands are used.

High dynamic proportional valves and a constant output pump are adopted, so as to have a precise adjustment to the oil flow and pressure, which can provide the client with a stronger quality block, more efficient and energy-saving production.

3、Multi-shaft rotating in 360°and compulsory feeding design are used, greatly improving the density and intensity for the blocks while shortening the time for material feeding.

4. Integrated design on the vibration table not only can reduce the QT10 Concrete Brick Machine weight but also it can improve the vibration efficiently.

5. By adopting the double-line aero vibration-proof system, it can reduce the vibrating force on the mechanical parts, prolonging the machine's lifetime and reducing the noise.

6. High-precision guide bearings are used to assure the precise movement between the tamper head and the mold;

7. High-intensity steel and heat treatment are used for the machine frame, which allows the QT10 Concrete Brick Machine to have a better performance on wear-resistant.

Technical Data

| Moulding Cycle | 15-30s |

| Vibration Force | 100KN |

| Motor Frequency | 50-60HZ |

| Total Power | 52KW |

| Total Weight | 7.5T |

| Machine Size | 8,100*4,450*3,000mm |

Production Capacity

| Block Type | Dimension(mm) | Pictures | Qty/Cycle |

Production Capacity (Per 8hs) |

| Hollow Block | 400*200*200 |

|

6 | 11,000-14,000 |

| Rectangular Paver | 200*100*60 |

|

21 | 38,500-49,000 |

| Paver | 225*112,5*60 |

|

15 | 29,700-37,800 |

| Curstone | 500*150*300 |

|

2 | 4,400-5,600 |