English

English  Esperanto

Esperanto Afrikaans

Afrikaans Català

Català שפה עברית

שפה עברית Cymraeg

Cymraeg Galego

Galego Latviešu

Latviešu icelandic

icelandic ייִדיש

ייִדיש беларускі

беларускі Hrvatski

Hrvatski Kreyòl ayisyen

Kreyòl ayisyen Shqiptar

Shqiptar Malti

Malti lugha ya Kiswahili

lugha ya Kiswahili አማርኛ

አማርኛ Bosanski

Bosanski Frysk

Frysk ភាសាខ្មែរ

ភាសាខ្មែរ ქართული

ქართული ગુજરાતી

ગુજરાતી Hausa

Hausa Кыргыз тили

Кыргыз тили ಕನ್ನಡ

ಕನ್ನಡ Corsa

Corsa Kurdî

Kurdî മലയാളം

മലയാളം Maori

Maori Монгол хэл

Монгол хэл Hmong

Hmong IsiXhosa

IsiXhosa Zulu

Zulu Punjabi

Punjabi پښتو

پښتو Chichewa

Chichewa Samoa

Samoa Sesotho

Sesotho සිංහල

සිංහල Gàidhlig

Gàidhlig Cebuano

Cebuano Somali

Somali Тоҷикӣ

Тоҷикӣ O'zbek

O'zbek Hawaiian

Hawaiian سنڌي

سنڌي Shinra

Shinra Հայերեն

Հայերեն Igbo

Igbo Sundanese

Sundanese Lëtzebuergesch

Lëtzebuergesch Malagasy

Malagasy Yoruba

Yoruba অসমীয়া

অসমীয়া ଓଡିଆ

ଓଡିଆ Español

Español Português

Português русский

русский Français

Français 日本語

日本語 Deutsch

Deutsch tiếng Việt

tiếng Việt Italiano

Italiano Nederlands

Nederlands ภาษาไทย

ภาษาไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা ভাষার

বাংলা ভাষার Dansk

Dansk Suomi

Suomi हिन्दी

हिन्दी Pilipino

Pilipino Türkçe

Türkçe Gaeilge

Gaeilge العربية

العربية Indonesia

Indonesia Norsk

Norsk تمل

تمل český

český ελληνικά

ελληνικά український

український Javanese

Javanese فارسی

فارسی தமிழ்

தமிழ் తెలుగు

తెలుగు नेपाली

नेपाली Burmese

Burmese български

български ລາວ

ລາວ Latine

Latine Қазақша

Қазақша Euskal

Euskal Azərbaycan

Azərbaycan Slovenský jazyk

Slovenský jazyk Македонски

Македонски Lietuvos

Lietuvos Eesti Keel

Eesti Keel Română

Română Slovenski

Slovenski मराठी

मराठी Srpski језик

Srpski језик

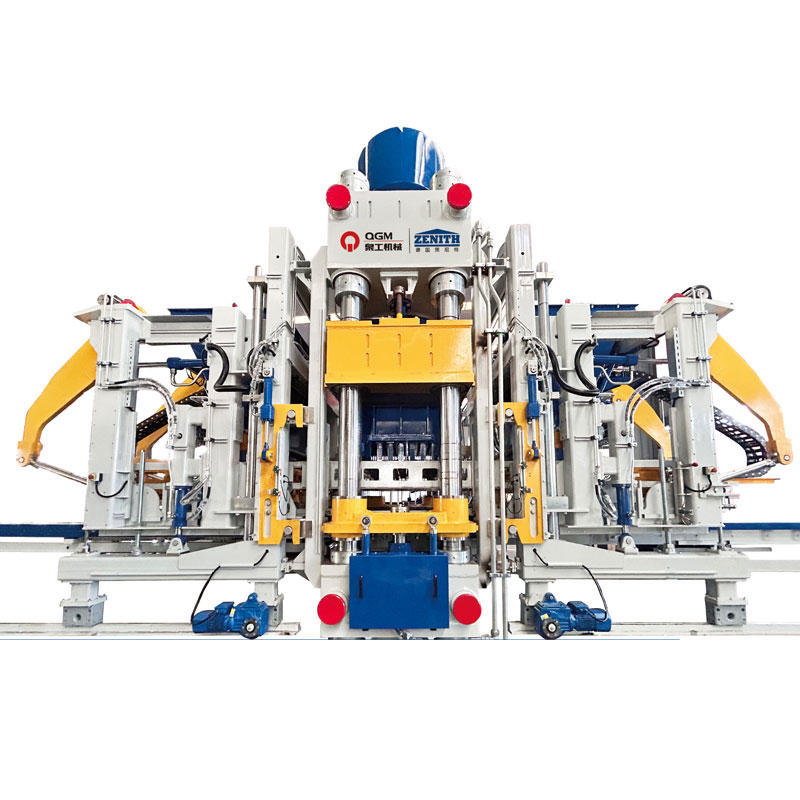

Fully Automation Production Line with Steel Curing Rack

Send Inquiry

Key Features and Benefits

Automation: These lines utilize advanced automation systems to control the entire production process, from material handling to curing. This reduces human intervention and ensures consistent quality.

Steel Curing Racks: The steel curing racks are designed to provide a stable and controlled environment for the curing process. They are typically made from high-quality stainless steel, which is resistant to corrosion and can withstand harsh conditions.

Temperature Control: The automated systems can precisely control the temperature of the curing racks, ensuring optimal curing conditions for different types of steel products.

Humidity Control: In some cases, humidity control may also be necessary for the curing process. Automated systems can regulate humidity levels to create the ideal environment for curing.

Efficiency: Fully automated lines significantly increase production efficiency by reducing downtime and manual labor.

Quality: Automated control systems help to ensure consistent product quality by maintaining precise curing parameters.

Safety: Automated systems can reduce the risk of accidents and injuries associated with manual handling of hot or heavy products.

1Cement Silo

2Batcher for Main Material

3Batcher for Facemix

4Screw Conveyor

5Water Weighing System

6Cement Weighing System

7Mixer for Main Material

8Mixer for Facemix

9Belt Conveyor for Main Material

10Belt Conveyor for Facemix

11Pallet Conveyor

12Automatic Block Making Machine

13Triangle Belt Conveyor

14Elevator

15Curing Racks

16Lowerator

17Lengthways Latch Conveyor

18Cuber

19Shipping Pallet Magazine

20Pallet Brush

21Transverse Latch Conveyor

22Pallet Turning Device

23Chain Conveyor

24Central Control System