English

English  Esperanto

Esperanto Afrikaans

Afrikaans Català

Català שפה עברית

שפה עברית Cymraeg

Cymraeg Galego

Galego Latviešu

Latviešu icelandic

icelandic ייִדיש

ייִדיש беларускі

беларускі Hrvatski

Hrvatski Kreyòl ayisyen

Kreyòl ayisyen Shqiptar

Shqiptar Malti

Malti lugha ya Kiswahili

lugha ya Kiswahili አማርኛ

አማርኛ Bosanski

Bosanski Frysk

Frysk ភាសាខ្មែរ

ភាសាខ្មែរ ქართული

ქართული ગુજરાતી

ગુજરાતી Hausa

Hausa Кыргыз тили

Кыргыз тили ಕನ್ನಡ

ಕನ್ನಡ Corsa

Corsa Kurdî

Kurdî മലയാളം

മലയാളം Maori

Maori Монгол хэл

Монгол хэл Hmong

Hmong IsiXhosa

IsiXhosa Zulu

Zulu Punjabi

Punjabi پښتو

پښتو Chichewa

Chichewa Samoa

Samoa Sesotho

Sesotho සිංහල

සිංහල Gàidhlig

Gàidhlig Cebuano

Cebuano Somali

Somali Тоҷикӣ

Тоҷикӣ O'zbek

O'zbek Hawaiian

Hawaiian سنڌي

سنڌي Shinra

Shinra Հայերեն

Հայերեն Igbo

Igbo Sundanese

Sundanese Lëtzebuergesch

Lëtzebuergesch Malagasy

Malagasy Yoruba

Yoruba অসমীয়া

অসমীয়া ଓଡିଆ

ଓଡିଆ Español

Español Português

Português русский

русский Français

Français 日本語

日本語 Deutsch

Deutsch tiếng Việt

tiếng Việt Italiano

Italiano Nederlands

Nederlands ภาษาไทย

ภาษาไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা ভাষার

বাংলা ভাষার Dansk

Dansk Suomi

Suomi हिन्दी

हिन्दी Pilipino

Pilipino Türkçe

Türkçe Gaeilge

Gaeilge العربية

العربية Indonesia

Indonesia Norsk

Norsk تمل

تمل český

český ελληνικά

ελληνικά український

український Javanese

Javanese فارسی

فارسی தமிழ்

தமிழ் తెలుగు

తెలుగు नेपाली

नेपाली Burmese

Burmese български

български ລາວ

ລາວ Latine

Latine Қазақша

Қазақша Euskal

Euskal Azərbaycan

Azərbaycan Slovenský jazyk

Slovenský jazyk Македонски

Македонски Lietuvos

Lietuvos Eesti Keel

Eesti Keel Română

Română Slovenski

Slovenski मराठी

मराठी Srpski језик

Srpski језик

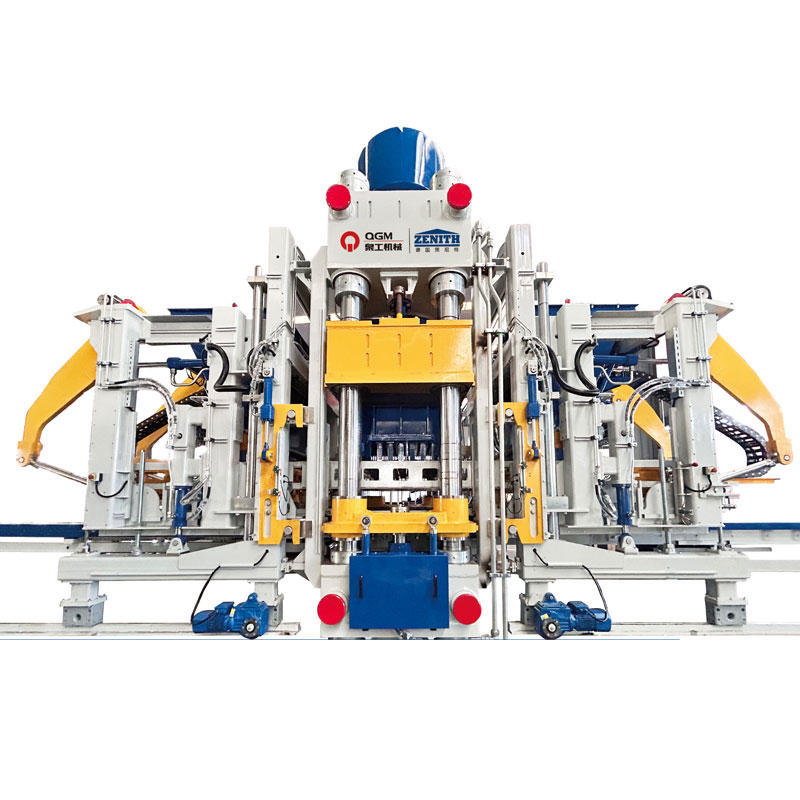

Automatic Production Line with Curing Racks

Send Inquiry

You can rest assured to buy Automatic Production Line with Curing Racks from our factory. Automated production lines equipped with curing racks are essential for industries that require precise control over the curing process of manufactured products. These lines are designed to efficiently transport products through various stages of production, including curing, which is a critical step in ensuring the quality and durability of finished goods.

Key Components and Features

Conveyor System: A robust conveyor system is used to transport products through the production line, including the curing racks.

Curing Racks: These specialized racks are designed to hold products during the curing process. They may be equipped with heating elements, ventilation systems, or other features to optimize the curing environment.

Automation Controls: Advanced automation controls are used to manage the entire production process, including the movement of products, temperature control, and timing of the curing process.

Sensors: Sensors are used to monitor various parameters, such as temperature, humidity, and product position, to ensure optimal curing conditions.

1Cement Silo

2Screw Conveyor

3Batcher for Main Material

4Mixer for Main Material

5Batcher for Facemix

6Mixer for Facemix

7Belt Conveyor for Main Material

8Belt Conveyor for Facemix

9Automatic Pallet Feeder Automatic Concrete

10Block Machine

11Central Control Room

12Elevator

13Curing and Transportation Racks

14Lowerator

15Blocks Pusher

16Pallet Collector

17Rotating Table

18Finished Block Cube