English

English  Esperanto

Esperanto Afrikaans

Afrikaans Català

Català שפה עברית

שפה עברית Cymraeg

Cymraeg Galego

Galego Latviešu

Latviešu icelandic

icelandic ייִדיש

ייִדיש беларускі

беларускі Hrvatski

Hrvatski Kreyòl ayisyen

Kreyòl ayisyen Shqiptar

Shqiptar Malti

Malti lugha ya Kiswahili

lugha ya Kiswahili አማርኛ

አማርኛ Bosanski

Bosanski Frysk

Frysk ភាសាខ្មែរ

ភាសាខ្មែរ ქართული

ქართული ગુજરાતી

ગુજરાતી Hausa

Hausa Кыргыз тили

Кыргыз тили ಕನ್ನಡ

ಕನ್ನಡ Corsa

Corsa Kurdî

Kurdî മലയാളം

മലയാളം Maori

Maori Монгол хэл

Монгол хэл Hmong

Hmong IsiXhosa

IsiXhosa Zulu

Zulu Punjabi

Punjabi پښتو

پښتو Chichewa

Chichewa Samoa

Samoa Sesotho

Sesotho සිංහල

සිංහල Gàidhlig

Gàidhlig Cebuano

Cebuano Somali

Somali Тоҷикӣ

Тоҷикӣ O'zbek

O'zbek Hawaiian

Hawaiian سنڌي

سنڌي Shinra

Shinra Հայերեն

Հայերեն Igbo

Igbo Sundanese

Sundanese Lëtzebuergesch

Lëtzebuergesch Malagasy

Malagasy Yoruba

Yoruba অসমীয়া

অসমীয়া ଓଡିଆ

ଓଡିଆ Español

Español Português

Português русский

русский Français

Français 日本語

日本語 Deutsch

Deutsch tiếng Việt

tiếng Việt Italiano

Italiano Nederlands

Nederlands ภาษาไทย

ภาษาไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা ভাষার

বাংলা ভাষার Dansk

Dansk Suomi

Suomi हिन्दी

हिन्दी Pilipino

Pilipino Türkçe

Türkçe Gaeilge

Gaeilge العربية

العربية Indonesia

Indonesia Norsk

Norsk تمل

تمل český

český ελληνικά

ελληνικά український

український Javanese

Javanese فارسی

فارسی தமிழ்

தமிழ் తెలుగు

తెలుగు नेपाली

नेपाली Burmese

Burmese български

български ລາວ

ລາວ Latine

Latine Қазақша

Қазақша Euskal

Euskal Azərbaycan

Azərbaycan Slovenský jazyk

Slovenský jazyk Македонски

Македонски Lietuvos

Lietuvos Eesti Keel

Eesti Keel Română

Română Slovenski

Slovenski मराठी

मराठी Srpski језик

Srpski језик

Quangong Brick Making Laboratory Achieves New Breakthrough in Co-utilization of Multi-Source Solid Waste

2025-12-22

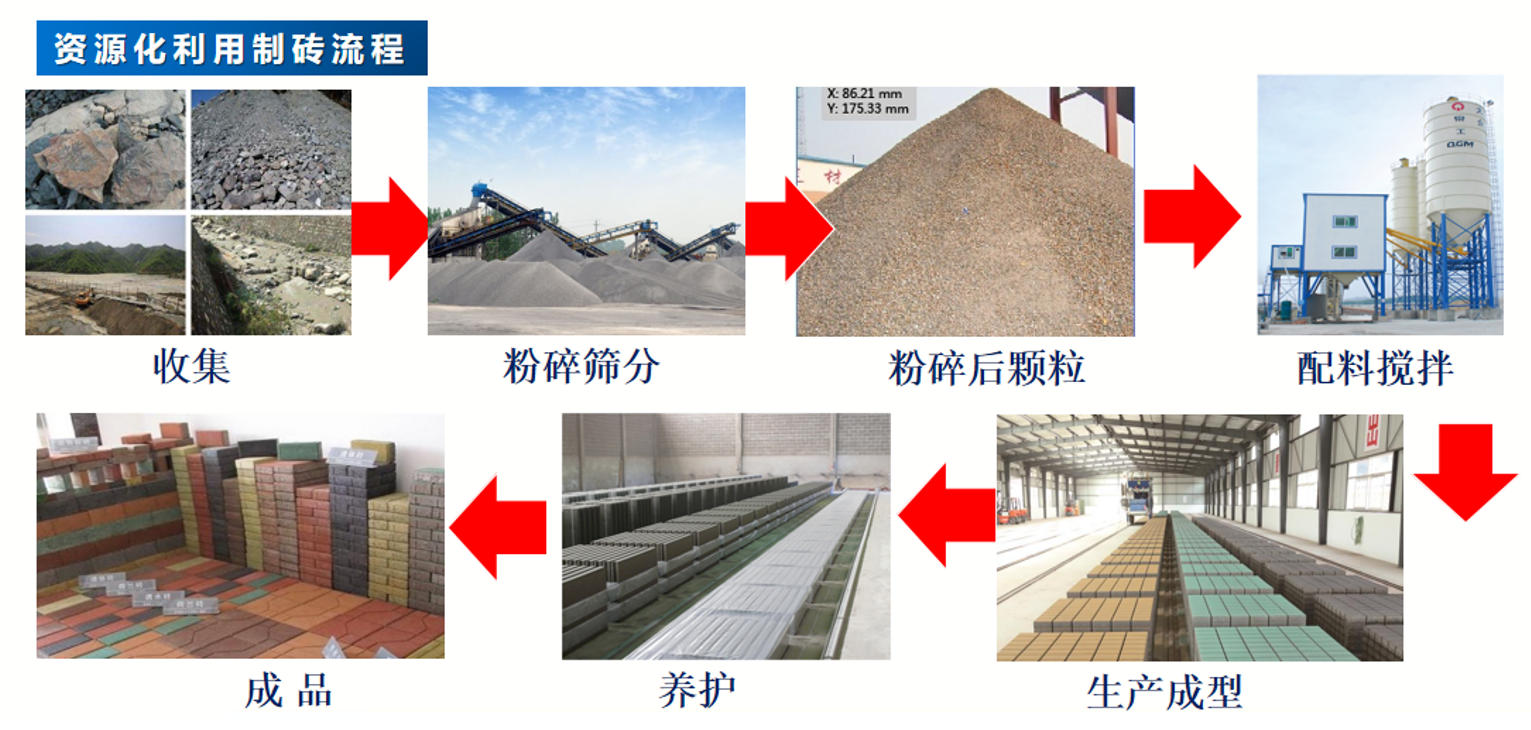

Quanzhou Gong Machinery Co., Ltd. continues to deeply cultivate the field of solid waste resource utilization and constantly explores green building material equipment and process innovation. Recently, Quanzhou Gong's brick-making laboratory has achieved phased results in the research of solid waste brick-making technology. It has successfully completed the standard brick preparation experiment using three types of solid waste—incineration ash, phosphorus slag, and coal gangue—as the main raw materials, providing a feasible path for the high-value utilization of multi-source solid waste.

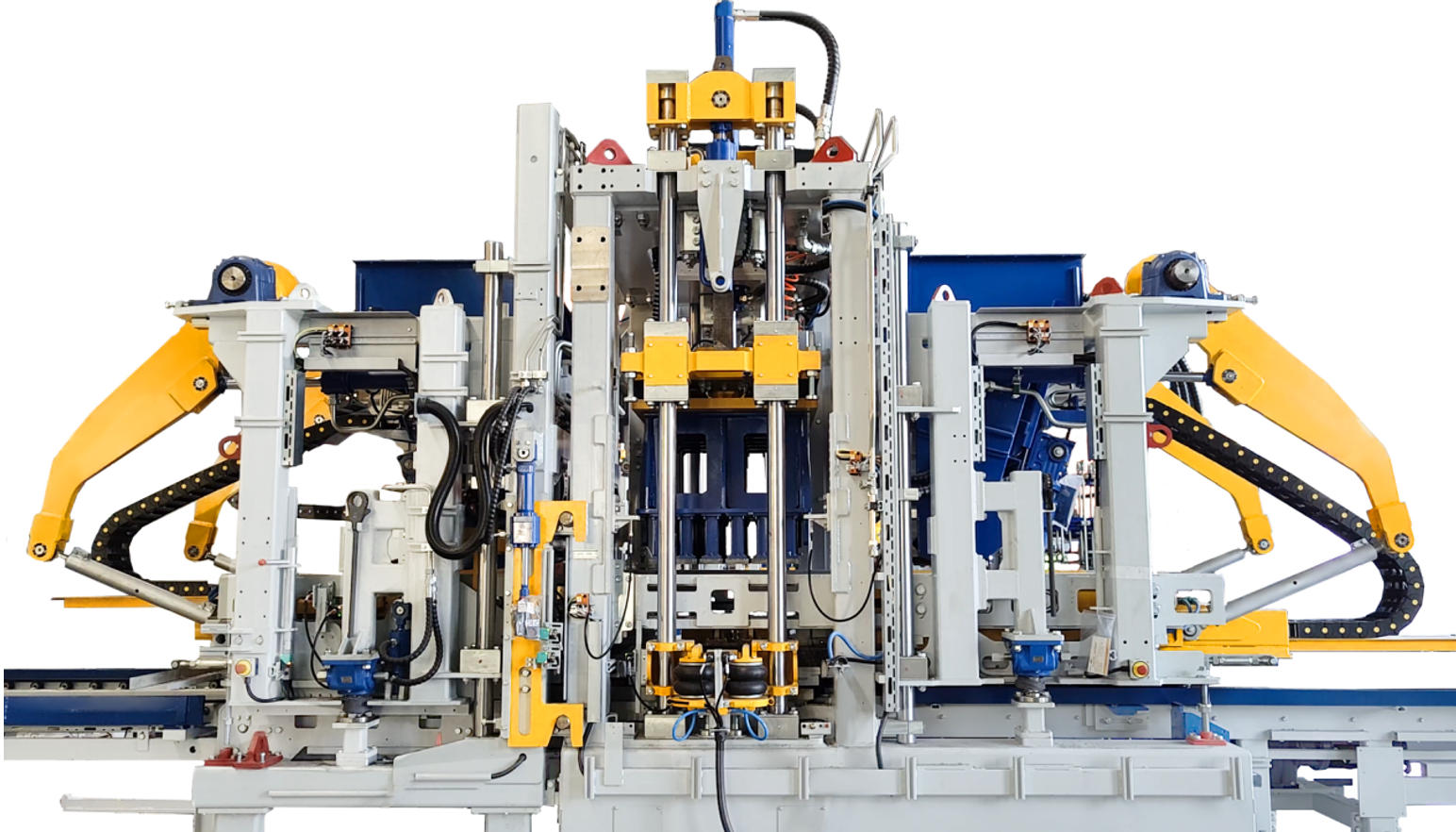

Incineration ash, phosphorus slag, and coal gangue are widely sourced and have complex compositions, facing significant challenges in their treatment and disposal for a long time. Quanzhou Gong brick-making laboratory, relying on comprehensive testing facilities and a professional technical team, conducted component analysis and proportion optimization of these three solid wastes. Combining the physical properties and chemical reactivity of different materials, it developed targeted brick-making process solutions. During the experiments, the laboratory used mature and reliable brick-making equipment for molding tests. Through multiple rounds of parameter adjustments and process verification, it successfully produced standard non-fired bricks that met the requirements for strength, size, and appearance.

This experimental result not only verifies the feasibility of co-processing bricks from multiple solid wastes, but also further demonstrates the technological advantages of non-fired brick machines in the resource utilization of solid waste. Through the non-fired molding process, solid waste can be transformed into stable block products without high-temperature calcination, effectively reducing energy consumption and carbon emissions, aligning with the current trend of green building materials development under the "dual carbon" background. This technological breakthrough marks a solid step forward for Quanzhou Machinery in the field of co-processing and high-value utilization of complex multi-source solid waste, providing a more universal and economical innovative solution for the construction of "zero-waste cities."