English

English  Esperanto

Esperanto Afrikaans

Afrikaans Català

Català שפה עברית

שפה עברית Cymraeg

Cymraeg Galego

Galego Latviešu

Latviešu icelandic

icelandic ייִדיש

ייִדיש беларускі

беларускі Hrvatski

Hrvatski Kreyòl ayisyen

Kreyòl ayisyen Shqiptar

Shqiptar Malti

Malti lugha ya Kiswahili

lugha ya Kiswahili አማርኛ

አማርኛ Bosanski

Bosanski Frysk

Frysk ភាសាខ្មែរ

ភាសាខ្មែរ ქართული

ქართული ગુજરાતી

ગુજરાતી Hausa

Hausa Кыргыз тили

Кыргыз тили ಕನ್ನಡ

ಕನ್ನಡ Corsa

Corsa Kurdî

Kurdî മലയാളം

മലയാളം Maori

Maori Монгол хэл

Монгол хэл Hmong

Hmong IsiXhosa

IsiXhosa Zulu

Zulu Punjabi

Punjabi پښتو

پښتو Chichewa

Chichewa Samoa

Samoa Sesotho

Sesotho සිංහල

සිංහල Gàidhlig

Gàidhlig Cebuano

Cebuano Somali

Somali Тоҷикӣ

Тоҷикӣ O'zbek

O'zbek Hawaiian

Hawaiian سنڌي

سنڌي Shinra

Shinra Հայերեն

Հայերեն Igbo

Igbo Sundanese

Sundanese Lëtzebuergesch

Lëtzebuergesch Malagasy

Malagasy Yoruba

Yoruba অসমীয়া

অসমীয়া ଓଡିଆ

ଓଡିଆ Español

Español Português

Português русский

русский Français

Français 日本語

日本語 Deutsch

Deutsch tiếng Việt

tiếng Việt Italiano

Italiano Nederlands

Nederlands ภาษาไทย

ภาษาไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা ভাষার

বাংলা ভাষার Dansk

Dansk Suomi

Suomi हिन्दी

हिन्दी Pilipino

Pilipino Türkçe

Türkçe Gaeilge

Gaeilge العربية

العربية Indonesia

Indonesia Norsk

Norsk تمل

تمل český

český ελληνικά

ελληνικά український

український Javanese

Javanese فارسی

فارسی தமிழ்

தமிழ் తెలుగు

తెలుగు नेपाली

नेपाली Burmese

Burmese български

български ລາວ

ລາວ Latine

Latine Қазақша

Қазақша Euskal

Euskal Azərbaycan

Azərbaycan Slovenský jazyk

Slovenský jazyk Македонски

Македонски Lietuvos

Lietuvos Eesti Keel

Eesti Keel Română

Română Slovenski

Slovenski मराठी

मराठी Srpski језик

Srpski језик

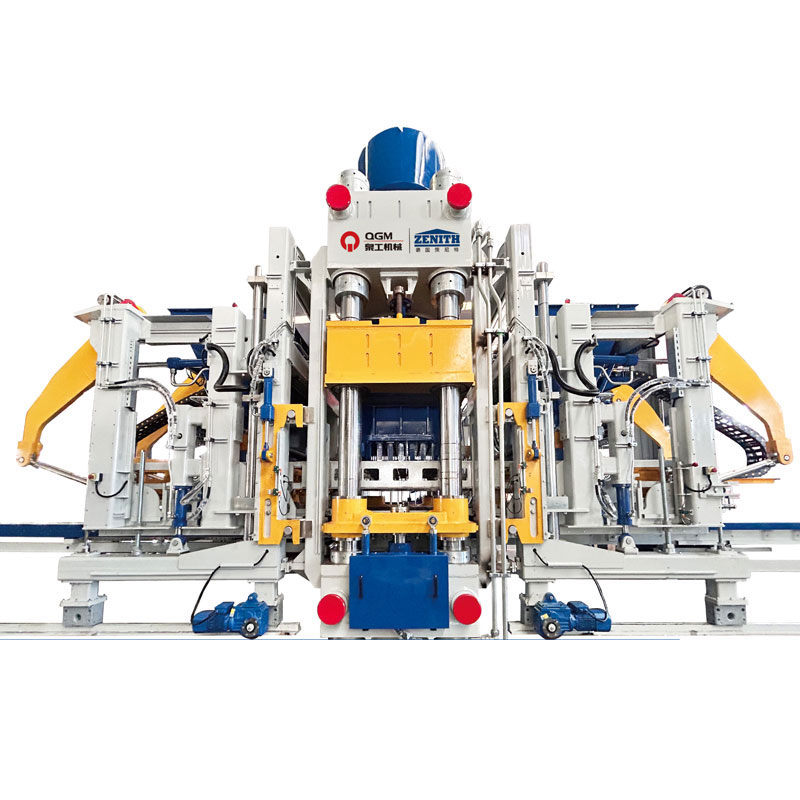

How to Select the Right Hydraulic Brick Press Based on Details

Static-pressed brick machines are the primary equipment used to produce new building products using fly ash, industrial tailings, slag, construction waste, and river sand as raw materials. They are called static-pressed brick machines because they produce no noise pollution during operation.

Main Features of Static-pressed Brick Machines:

Bricks produced by static-pressed brick machines do not require sintering; they only require natural curing or autoclaving. These machines meet national first-class brick standards and are ideal for increasing the recycling rate of waste resources, protecting land resources, alleviating environmental pressures, and producing green and environmentally friendly building materials. They are strongly supported and promoted by national policies. The four-column structure offers a compact design, a small footprint, excellent rigidity, strong stability, and smooth, noiseless operation. Advanced technology ensures the machine's multifunctional benefits, coupled with mature production technology, making it an ideal replacement for sintered clay brick machines.

Key advantages of static brick machines:

1. Wide range of raw materials and low production costs. Fly ash, industrial tailings, river sand, construction waste, and other materials can all be used as raw materials for static brick machines, effectively achieving the goal of recycling waste resources and turning waste into treasure, creating economic benefits.

2. Utilizing PLC hydraulic drive technology, the machine boasts high technological content and a high degree of automation, shortening the molding cycle, increasing the number of blocks formed, and significantly improving production output.

3. Automation reduces labor workload, allowing the formed products to be automatically stacked, saving significant manpower and time.

4. The machine can produce a variety of products by changing molds, such as standard bricks, hollow bricks, blind hole bricks, porous bricks, grass bricks, and square bricks, meeting market demand.

Static brick machines offer high molding pressure, high density, and high hardness. The produced bricks can be directly gripped and stacked by a stacker, eliminating the need for pallet maintenance. Traditional block machines require cement bricks to be placed on pallets and cured to a certain hardness before stacking.

How to choose?

1. Hydraulic press type selection: Hydraulic presses come in a variety of types, each with varying rigidity, precision, and applications. The appropriate choice should be based on the production process, batch size, mold requirements, and precision requirements. For large batch sizes and small and medium-sized parts, a crank hydraulic press with ease of operation and high production efficiency can be selected. For deep-drawn parts like laundry tubs, a hydraulic press designed for drawing should be selected.

2. Determine the purchase specifications based on your actual needs, adhering to the following principles:

① Users should understand the workpieces they will be processing and whether they have any special requirements for the hydraulic hydraulic brick press. At the same time, allow for margins to account for future expansion needs.

② The nominal pressure of the hydraulic brick press must be greater than the punching process force. However, for processes with long working strokes, it's not enough to simply meet the process force; the load curve must also be considered.

③ The number of strokes of the hydraulic brick press should meet productivity requirements. ④ The slide stroke of the static brick press should ensure that the workpiece reaches the required height and can be smoothly removed from the die after the stamping process is completed. For drawn parts, the stroke should be at least twice the workpiece height. The hydraulic press's closing height, worktable dimensions, slide dimensions, and die handle hole dimensions must all meet the requirements for proper mold installation. For crank presses, the die closing height should be between the press's maximum and minimum die heights. The worktable should generally be 50-70mm (per side) larger than the die base to facilitate installation. The backing plate aperture should be larger than the projected dimensions of the workpiece or scrap to prevent leakage. The die handle dimensions should match the die handle hole dimensions.

3. Choosing a Manufacturer

As the saying goes, a good tool must be sharp before you can do your job well. The quality of a static brick press directly impacts production efficiency. Choosing a reliable manufacturer is more important than any other factor. When selecting a hydraulic press, check the hydraulic press's design and whether the paint finish is even and smooth. A smooth surface with no pitting is preferred. In addition, it is essential to keep the static brick press in good condition and debug it correctly. Furthermore, the faster the hydraulic press rotates, the higher the production efficiency; weight can, to a certain extent, reflect the durability of the hydraulic brick press; low power consumption and low oil temperature mean a longer service life. The sealing performance of a static brick press directly affects its use and lifespan; a good hydraulic press will not leak oil. Furthermore, scientific material selection is also key to extending the service life of a hydraulic press. Therefore, it is important to be cautious not only when selecting a hydraulic press, but also when using it.

Quangong Machinery, a reputable Chinese manufacturer and a leading domestic block-forming machine manufacturer, adheres to the business philosophy of "Quality determines value, expertise makes a career." Integrating German technology, we actively innovate and develop our own core technologies. Our static block press is energy-efficient, high-speed, and affordable. It features a four-column press and hydraulic transmission.

| Aspect | Overview |

|---|---|

| Technology | Concise Technical Features |

| High-Quality Frame Design | Patent Design, Strong Steel, Stable. |

| Material Distribution System | Durable Placement, Efficient Feeding, Wear-Resistant. |

| High-Pressure Hydraulic System | High-Pressure Hydraulic, Fast & Stable, Energy-Saving. |

| Servo Control | Low Energy, Smooth Braking, Synchronization. |

| Fully Automated Control | Smart Operation, Labor-Saving, Stable. |