English

English  Esperanto

Esperanto Afrikaans

Afrikaans Català

Català שפה עברית

שפה עברית Cymraeg

Cymraeg Galego

Galego Latviešu

Latviešu icelandic

icelandic ייִדיש

ייִדיש беларускі

беларускі Hrvatski

Hrvatski Kreyòl ayisyen

Kreyòl ayisyen Shqiptar

Shqiptar Malti

Malti lugha ya Kiswahili

lugha ya Kiswahili አማርኛ

አማርኛ Bosanski

Bosanski Frysk

Frysk ភាសាខ្មែរ

ភាសាខ្មែរ ქართული

ქართული ગુજરાતી

ગુજરાતી Hausa

Hausa Кыргыз тили

Кыргыз тили ಕನ್ನಡ

ಕನ್ನಡ Corsa

Corsa Kurdî

Kurdî മലയാളം

മലയാളം Maori

Maori Монгол хэл

Монгол хэл Hmong

Hmong IsiXhosa

IsiXhosa Zulu

Zulu Punjabi

Punjabi پښتو

پښتو Chichewa

Chichewa Samoa

Samoa Sesotho

Sesotho සිංහල

සිංහල Gàidhlig

Gàidhlig Cebuano

Cebuano Somali

Somali Тоҷикӣ

Тоҷикӣ O'zbek

O'zbek Hawaiian

Hawaiian سنڌي

سنڌي Shinra

Shinra Հայերեն

Հայերեն Igbo

Igbo Sundanese

Sundanese Lëtzebuergesch

Lëtzebuergesch Malagasy

Malagasy Yoruba

Yoruba অসমীয়া

অসমীয়া ଓଡିଆ

ଓଡିଆ Español

Español Português

Português русский

русский Français

Français 日本語

日本語 Deutsch

Deutsch tiếng Việt

tiếng Việt Italiano

Italiano Nederlands

Nederlands ภาษาไทย

ภาษาไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা ভাষার

বাংলা ভাষার Dansk

Dansk Suomi

Suomi हिन्दी

हिन्दी Pilipino

Pilipino Türkçe

Türkçe Gaeilge

Gaeilge العربية

العربية Indonesia

Indonesia Norsk

Norsk تمل

تمل český

český ελληνικά

ελληνικά український

український Javanese

Javanese فارسی

فارسی தமிழ்

தமிழ் తెలుగు

తెలుగు नेपाली

नेपाली Burmese

Burmese български

български ລາວ

ລາວ Latine

Latine Қазақша

Қазақша Euskal

Euskal Azərbaycan

Azərbaycan Slovenský jazyk

Slovenský jazyk Македонски

Македонски Lietuvos

Lietuvos Eesti Keel

Eesti Keel Română

Română Slovenski

Slovenski मराठी

मराठी Srpski језик

Srpski језик

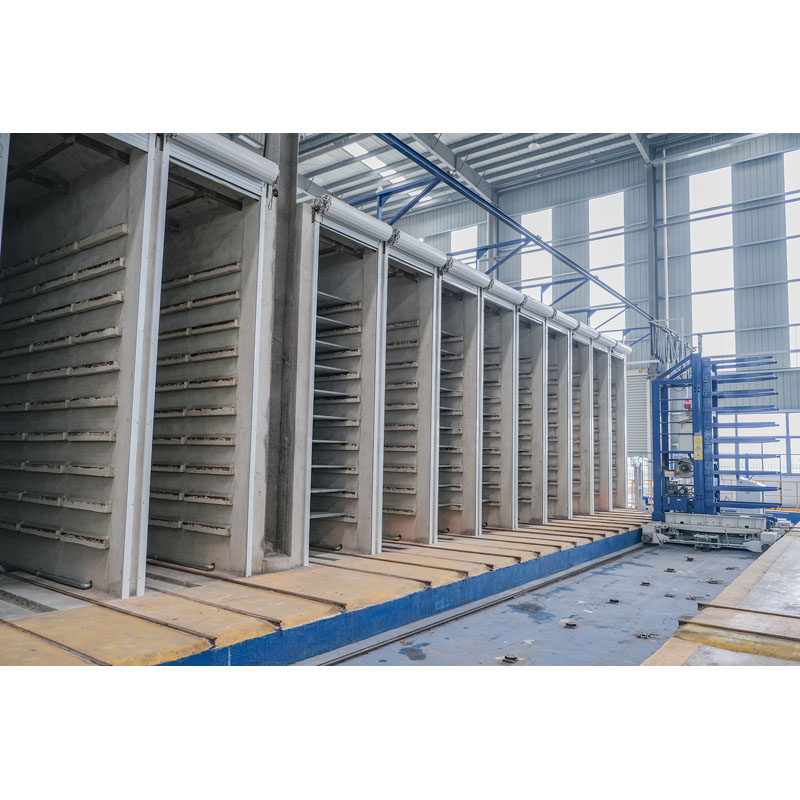

Why is the Brick Machine Curing Room a critical facility for improving brick quality?

2025-07-30

After participating in multiple brick production line projects, I've come to realize that brick curing often determines the final strength and appearance of the product. Unfortunately, this is precisely the aspect that many clients tend to overlook during initial planning. What truly reassured me about this step was the changes I saw after using the Brick Machine Curing Room. Its impact far exceeded my expectations and redefined what it means to "improve quality from the source."

Can common brick curing problems be systematically addressed?

In the past, we often encountered cracking, warping, and uneven strength in bricks during production. Sometimes, even slightly dry weather would result in a batch of unqualified products, leading to significant losses. However, since we introduced the Brick Machine Curing Room in our projects, bricks are cured in a constant temperature and humidity environment. Not only has the surface cracking been reduced, but the internal structure has also become more compact, significantly improving the yield rate. This stable, enclosed curing environment is simply unmatched by manual outdoor curing.

Is this equipment complex? Can it be flexibly adapted to different factories?

This is a common question many customers ask me when they first contact us. I was initially concerned about the complexity of the equipment installation and whether it would require major site modifications, but these concerns proved unfounded. The Brick Machine Curing Room features a modular structure, allowing for flexible deployment in various factory conditions. Whether it's for a new production line or an existing factory renovation, it's been a smooth process. QGM's on-site support was also prompt, with detailed drawings and clear construction schedules. The main structural installation was completed within a few days.

Is the operating cost high? Can energy conservation and efficiency be balanced?

For a curing system, stability is a fundamental requirement, and energy conservation is a key long-term consideration. The Brick Machine Curing Room we currently use offers this. It features an automated control system that adjusts humidity and temperature according to the season and brick type, minimizing resource waste. Furthermore, the room is well-sealed, minimizing heat loss, and even running it 24/7 doesn't incur high costs. Thanks to this system, our factory's curing costs decreased by approximately 18% last year compared to the year before—a truly profitable investment.

How has the experience been? Are customers satisfied?

I've worked on numerous projects, from the frigid north to the humid south, and the Brick Machine Curing Room has proven remarkably stable in diverse climates. The bricks are smoother and stronger, and customers generally pass inspections on the first try. Several established customers have even expressed their desire to continue using this configuration for their next production line. I think this is direct recognition.

Beyond output, what should brick factories focus on?

In the past, we often assumed that higher brick machine capacity was better. Now, it seems that stable quality, manageable costs, and low scrap rates are the keys to sustainable development. The Brick Machine Curing Room provides solutions in precisely these areas. If you're looking to upgrade your production line, reduce labor reliance, or improve product consistency, this system is definitely worth serious consideration.

Our products are highly reliable. If you have any needs, please feel free to contact us. We're available 24/7 to provide efficient solutions.