English

English  Esperanto

Esperanto Afrikaans

Afrikaans Català

Català שפה עברית

שפה עברית Cymraeg

Cymraeg Galego

Galego Latviešu

Latviešu icelandic

icelandic ייִדיש

ייִדיש беларускі

беларускі Hrvatski

Hrvatski Kreyòl ayisyen

Kreyòl ayisyen Shqiptar

Shqiptar Malti

Malti lugha ya Kiswahili

lugha ya Kiswahili አማርኛ

አማርኛ Bosanski

Bosanski Frysk

Frysk ភាសាខ្មែរ

ភាសាខ្មែរ ქართული

ქართული ગુજરાતી

ગુજરાતી Hausa

Hausa Кыргыз тили

Кыргыз тили ಕನ್ನಡ

ಕನ್ನಡ Corsa

Corsa Kurdî

Kurdî മലയാളം

മലയാളം Maori

Maori Монгол хэл

Монгол хэл Hmong

Hmong IsiXhosa

IsiXhosa Zulu

Zulu Punjabi

Punjabi پښتو

پښتو Chichewa

Chichewa Samoa

Samoa Sesotho

Sesotho සිංහල

සිංහල Gàidhlig

Gàidhlig Cebuano

Cebuano Somali

Somali Тоҷикӣ

Тоҷикӣ O'zbek

O'zbek Hawaiian

Hawaiian سنڌي

سنڌي Shinra

Shinra Հայերեն

Հայերեն Igbo

Igbo Sundanese

Sundanese Lëtzebuergesch

Lëtzebuergesch Malagasy

Malagasy Yoruba

Yoruba অসমীয়া

অসমীয়া ଓଡିଆ

ଓଡିଆ Español

Español Português

Português русский

русский Français

Français 日本語

日本語 Deutsch

Deutsch tiếng Việt

tiếng Việt Italiano

Italiano Nederlands

Nederlands ภาษาไทย

ภาษาไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা ভাষার

বাংলা ভাষার Dansk

Dansk Suomi

Suomi हिन्दी

हिन्दी Pilipino

Pilipino Türkçe

Türkçe Gaeilge

Gaeilge العربية

العربية Indonesia

Indonesia Norsk

Norsk تمل

تمل český

český ελληνικά

ελληνικά український

український Javanese

Javanese فارسی

فارسی தமிழ்

தமிழ் తెలుగు

తెలుగు नेपाली

नेपाली Burmese

Burmese български

български ລາວ

ລາວ Latine

Latine Қазақша

Қазақша Euskal

Euskal Azərbaycan

Azərbaycan Slovenský jazyk

Slovenský jazyk Македонски

Македонски Lietuvos

Lietuvos Eesti Keel

Eesti Keel Română

Română Slovenski

Slovenski मराठी

मराठी Srpski језик

Srpski језик

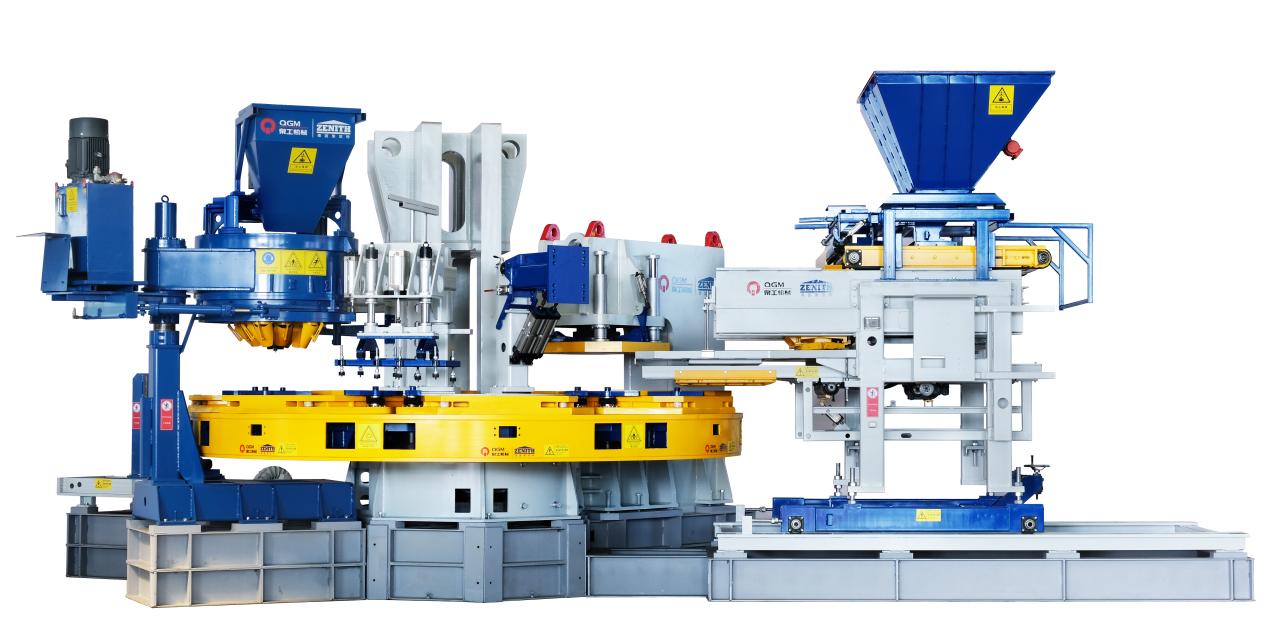

New Choice for Building Empowerment: Wet Brick Making Machine

2025-02-07

Quangong wet brick making machine is an efficient brick making equipment using wet process. Different from dry brick making, wet brick making adds an appropriate amount of water to the raw materials to form a fluid slurry, and then uses a high-pressure molding process to produce high-strength and high-precision bricks. This equipment is widely used in the production of large slab bricks, curbstones, imitation stone bricks, decorative bricks and other high-end building materials.

Representative model 1200T static press:

Wet-process brick making machines can use solid waste resources such as waste slag and fly ash as raw materials, greatly reducing resource waste. The entire production process has low energy consumption and low emissions, and meets national green building material standards. Intelligent operation improves production efficiency. The equipment is equipped with an advanced PLC intelligent control system to achieve fully automated operation, reduce manual intervention, improve production efficiency, and automatically feed, grouting and demoulding processes to ensure that the quality of each brick is consistent. Quangong wet-process brick making machines use core components imported from Germany, and the equipment operates stably and has excellent performance. The modular design facilitates daily maintenance, reduces downtime, and improves production stability.

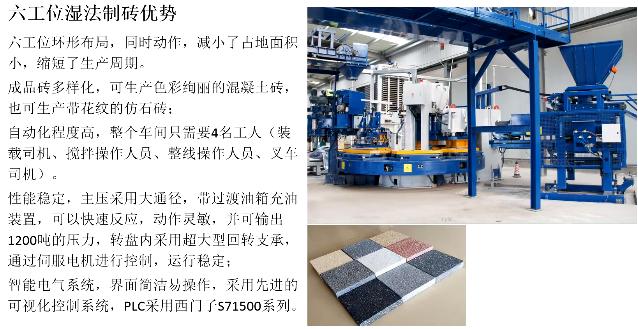

Advantages of six-station wet brick making

The six-station circular layout and simultaneous operation reduce the floor space and shorten the production cycle.

The finished bricks are diversified, and can produce colorful concrete bricks or imitation stone bricks with patterns;

The degree of automation is high, and only 4 workers are needed in the entire workshop (loader, mixing operator, whole line operator, forklift driver).

The performance is stable, the main pressure adopts a large diameter, with a transition tank filling device, which can respond quickly, move sensitively, and can output 1200 tons of pressure. The turntable adopts an ultra-large slewing bearing, which is controlled by a servo motor and runs stably;

The intelligent electrical system has a simple and easy-to-operate interface, adopts an advanced visual control system, and the PLC adopts the Siemens S71500 series.

The bricks produced by QGM wet-process brick making machine have smooth surface, fine texture, extremely high dimensional accuracy and compressive strength. Under the dual demands of environmental protection and efficient production in the construction industry, QGM wet-process brick making machine has become a popular choice in the market with its advanced technology and excellent performance. QGM wet-process brick making machine not only meets the demand of modern construction for high-quality bricks, but also demonstrates strong advantages in environmental protection and sustainable development.